NICKEL

Quote, Buy, Track!

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

Plate Thickness Variations

Plate Thickness Variation Back To All Articles Share: More Articles Quote, Buy, Track! We make it easy to get instant

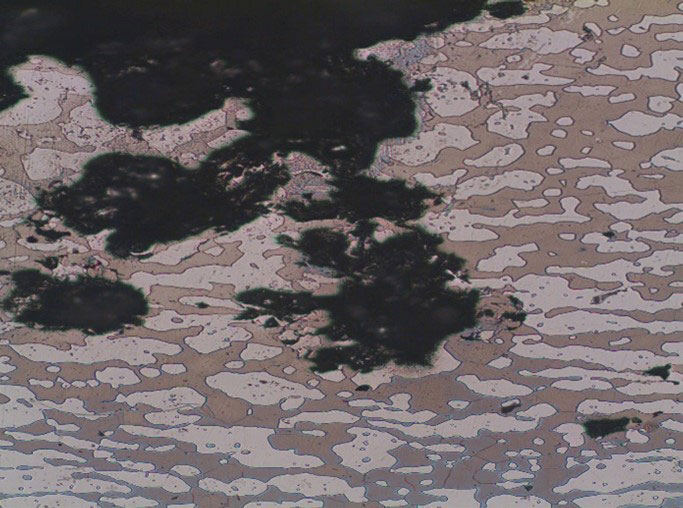

Best Practices When Using Duplex Stainless Steels

Gain deeper insight into duplex stainless steel and master best practices in metallurgy for peak performance in demanding applications.

Things to Know About PREN

Highlighting the importance of factors beyond PREN, like manufacturing processes and heat treatment, is essential for predicting corrosion resistance accurately

Rolled Alloys is Coming to Tampa!

Coming to Tampa, Florida – Summer 2024 Back To All Articles Share: Quote, Buy, Track! We make it easy to

RA330®

RA330® is a patented alloy designed specifically for the heat treatment industry. To this day RA330 outperforms the generic version made only to UNS N08330. In addition to meeting the requirements of UNS N08330, Rolled Alloys has tighter chemistry restrictions and proprietary heat treatments to produce an optimum product. Even the weld wire, RA330-04, has increased levels of manganese to avoid hot cracking. When buying a heat resistant alloy, insist on quality, insist it is RA330.

RA330 alloy is an austenitic heat and corrosion resisting alloy offering an exceptional combination of strength and resistance to carburization, oxidation and thermal shock. Carburization and oxidation resistance to 2100°F (1148°C) are enhanced by a nominal 1.25% silicon addition. RA330 alloy finds wide application in high temperature industrial environments where good resistance to the combined effects of carburization and thermal cycling are required. RA330 alloy remains fully austenitic at all temperatures and is not subject to embrittlement from sigma formation.

- Oxidation resistance to 2100°F (1148°C)

- Resistant to carburization and nitriding

- Resistance to thermal shock

- Good strength at elevated temperature

- Metallurgical stability

UNS: N08330

W. NR.: 1.4886

EN: 10095

ASTM: B 536, B 511, B 512, B 535, B 546, B 710, B 739

ASME: SB 536, SB 511, SB 535, SB 710

AMS: 5592, 5716

Incoloy Alloy 330, Alloy 330, UNS N08330

- Muffles

- Corrugated Boxes

- Retorts

- Bar Baskets

- Radiant Tubes

Rolled Alloys and our RA330 alloy were both created to service the need of the thermal process industries for a reliable source of a wrought alloy that could handle the rigors high temperature carburizing conditions and repeated quenching. Both our company and our RA330 alloy product began as parts of the Michigan Steel Castings Company (MISCO). The predecessor to RA330 was an alloy known as MISCO metal, it was a rolled version of the cast HT alloy and 35% nickel, 15% chromium. Its success came as a replacement to castings which were less ductile and fractured during harsh temperature cycling.

In 1953, Rolled Alloys became an independent company and MISCO metal became RA330 alloy. Over the past 60 years, we have applied our knowledge and close working relationship with the thermal process industry to modify RA330 to optimize its performance. These efforts include adjusting its chemistry to its current 35% nickel, 19% chromium, 1.25% silicon and controlled production techniques to ensure a product that has the optimal microstructure to withstand repeated thermal cycling.

Share This Page