Why Choose Rolled Alloys e-Services?

Our e-Services stocking programs put you in the driver’s seat by using our customized purchasing options to order your repetitive parts with ease. Whether you have an internal process for purchasing and receiving in place, or are looking for other solutions to become more efficient, we have a program that will work for you.

The best part? Our programs come with no additional cost!

What are e-Services Programs?

These inventory solutions are specifically customized for the material you order based on a set demand schedule or ever-changing due dates and quantities. We set up all parts on your program based on material requirements, specifications, and dimensions provided by your company. At any time, from anywhere, on any device – get access to your e-Services programs to place orders and track progression through our facility until it lands on your dock.

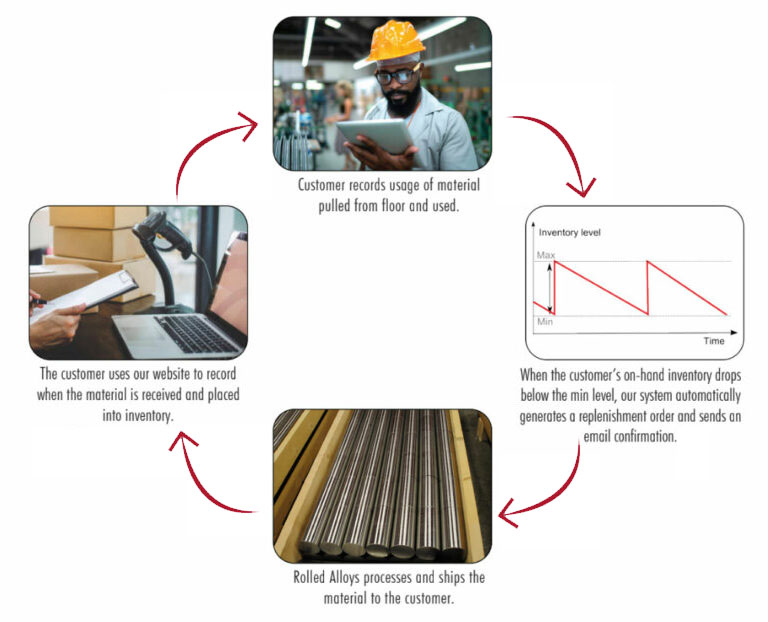

MIN/MAX PROGRAM

Program Overview:

The stock size or cut items are held on the customer’s floor, and the customer pulls the material from inventory and records usage. Once the inventory reaches or falls below min. level, an order is automatically generated and shipped to the customer to replenish the stock level. No waiting on processing and freight times.

Best for Customers Who:

- Require on-hand inventory at all times

- Need protection against stock-outs and shop delay

- View program requirements

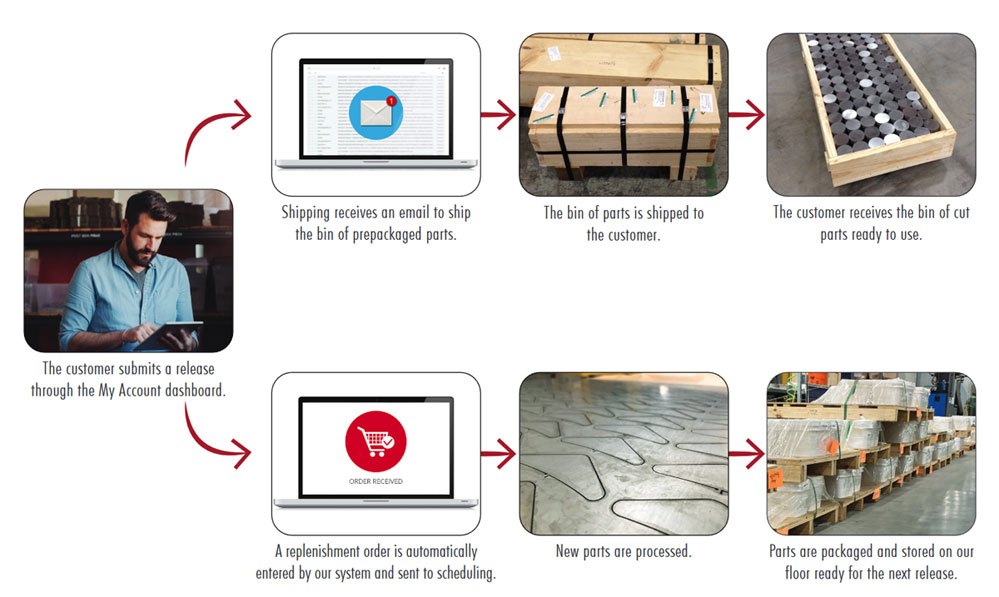

KANBAN PROGRAM

Program Overview:

The customer always has a release bin packed and held in the RA facility, ready to ship on their command.

Best for Customers Who:

- Need protection against stock-outs and shop delays

- Have limited floor space for inventory

- Use cut parts

- Practice JIT inventory model

- View program requirements

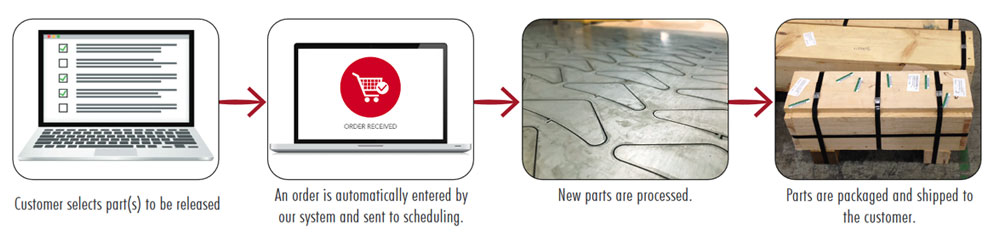

PART RELEASE

Program Overview:

The customer orders whatever quantity they want, when they want it. They can also create releases for future shipments through their My Account dashboard.

Best for Customers Who:

- Have flexibility of delivery for parts based on lead times

- Have limited floor space for inventory

- View program requirements

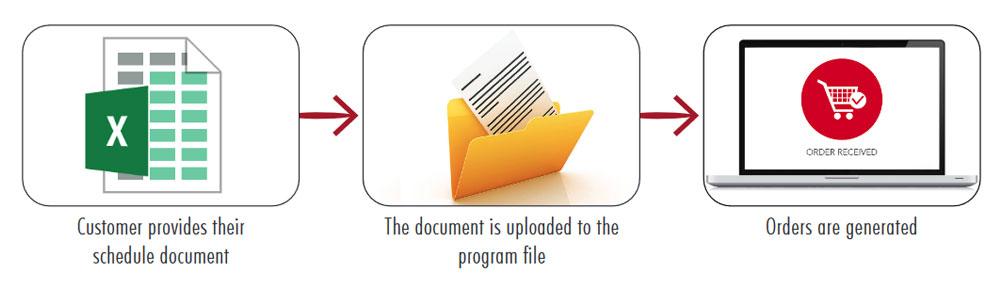

SCHEDULE INTEGRATION

Program Overview:

A timetable of planned or firm orders from customers that need the ability to make quick and seamless changes to dates and quantities. Requires contract or LTA pricing.

Best for Customers Who:

- Have high-transactional orders for recurring parts

- Need the ability to make changes to dates and quantities for orders

- View program requirements