Home » News & Articles » New Stainless Products 420 & 17-4 Flat Bar

420 Stainless Steel Bar

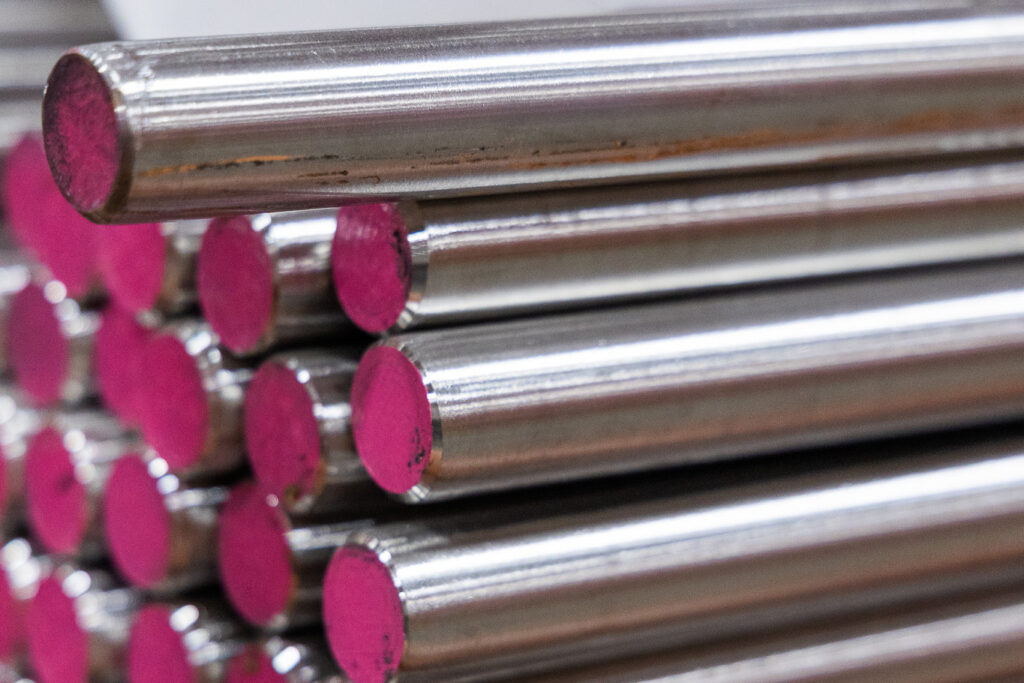

We’ve recently announced the addition of 420 Stainless Round Bar to its inventory. 420 is a 12% chromium, martensitic stainless steel. 420 provides improved hardenability and strength compared to 410 stainless. 420 stainless bar inventory meets DFARs sourcing requirements.

“With the addition of 420 stainless, we now offer more than 20 grades of stainless bar spanning every family from 300 & 400 series to duplex and precipitation hardening (PH) grades. Expanded inventories combined with our industry leading website and processing capabilities furthers our mission to be the easiest metals sourcing option.”

17-4 Flat Bar

17-4 stainless is an age-hardening martensitic stainless combining high strength with the corrosion resistance of stainless steel. Hardening is achieved by a short-time, simple low-temperature treatment. Unlike conventional martensitic stainless steels, such as type 410, 17-4 is quite weldable. The strength, corrosion resistance and simplified fabrication can make 17-4 stainless a cost-effective replacement for high strength carbon steels as well as other stainless grades.

Our bar processing options include precision sawing, band sawing, ink jet part marking, and XRF positive material verification.

We offer a diverse grade and product form portfolio of heat and corrosion resistant alloys across 13 locations in North America and Asia, with additional representation in Europe. Click here to learn more about us.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.