Home » News & Articles » History and Uses of Alloy 800

The Evolution of Alloy 800

Alloy 800 is a grade that has undergone significant changes over time, resulting in various derivatives. Since its introduction, it has been extensively utilized in the petrochemical and refining industries, particularly in applications requiring high strength at elevated temperatures. This guide provides an overview of the historical development of alloy 800, industrial applications, and current commercial availability.

Origins and Development

There are several distinct versions of alloy 800, which have evolved due to changes in alloying and grain size requirements, primarily driven by a means of enhancing the alloy properties. Understanding these variations is crucial when selecting the appropriate grade of 800 for an application.

The original alloy 800 was developed by Inco Alloys, now Special Metals Corporation, in the 1950s. It was created to meet the demand for a heat-resistant alloy with low nickel content, a necessity brought on by the nickel shortage during the Korean War. Before the introduction of alloy 800, the most commonly used heat-resistant alloy was alloy 600, which contained approximately 76% nickel in its composition.

Originally, alloy 800 was offered in two grades: Grade 1 and Grade 2. Grade 1 had a fine grain size and was typically annealed at approximately 1800°F. In contrast, Grade 2 underwent solution annealing at approximately 2100°F. This higher-temperature annealing process resulted in coarser grain sizes, which enhanced the alloy’s creep strength.

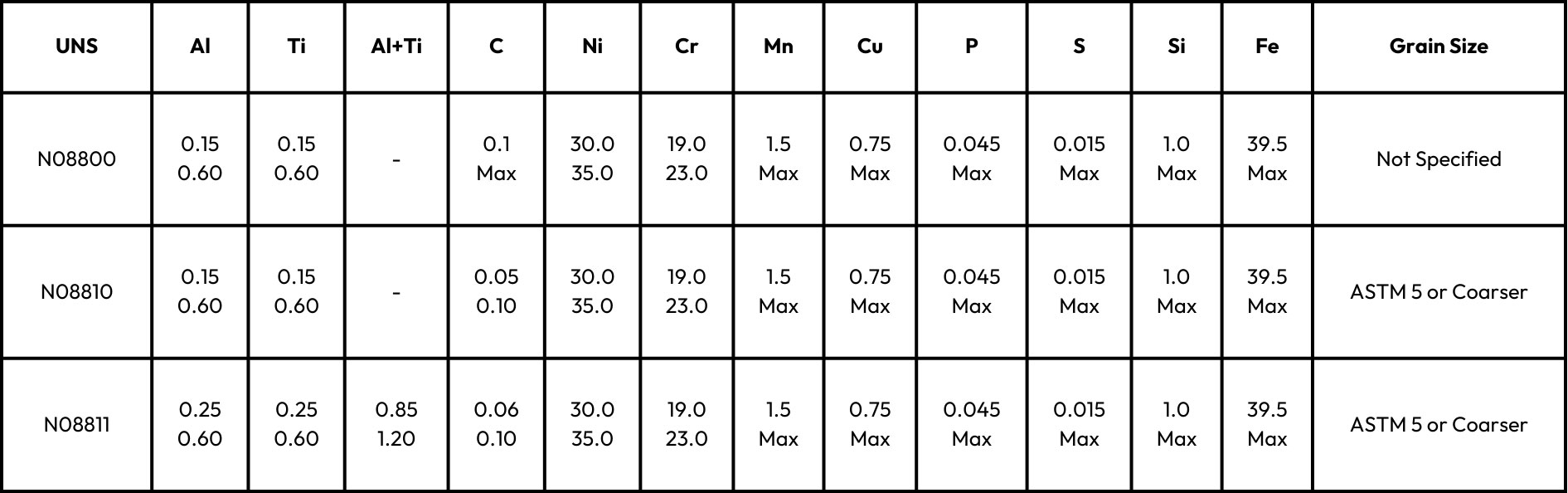

In the early 1970s, Grade 2 evolved into alloy 800H, establishing a minimum carbon content of 0.05% and a grain size requirement of ASTM 5 or coarser. During the 1980s, in an effort to enhance creep strength and obtain higher ASME allowable design stresses, the carbon content was adjusted to a range of 0.06% to 0.10%, the minimum for aluminum and titanium content were increased to 0.25%, and an aluminum plus titanium content requirement was established. As a result of these changes, Inco introduced this new grade as 800HT®.

After the patent for 800HT expired, other nickel alloy manufacturers began producing 800AT, a generic version of 800HT that shares the exact Unified Numbering System (UNS) designation.

Current Industrial Use

800H/AT is a high-strength alloy commonly used in the petrochemical and refining industries for various furnace components, including furnace cracker tubes, pigtails, calciners, and other equipment requiring high creep strength. Today, 800H/AT has one of the highest creep strengths among wrought alloys and some of the highest ASME allowable design stresses for a heat-resistant wrought alloy. This alloy achieves its strength through a combination of factors that include:

- Coarse grain size resulting from a minimum solution annealing temperature of 2100°F.

- High carbon content ranging from 0.06% to 0.10%.

- Total aluminum and titanium content of 0.85% to 1.20%.

Due to its coarse grain size, 800H/AT exhibits excellent creep resistance. However, it tends to have poor resistance to thermal shock and thermal cycling. As a result, 800H/AT is primarily used in high-temperature applications where the temperature does not fluctuate significantly in a cyclic manner.

In addition to its poor thermal cyclic resistance, 800H/AT is highly susceptible to stress relaxation cracking (SRC). This vulnerability is due to its coarse grain size and the presence of fine strengthening precipitates. Based on API 942-B, the best prevention against SRC is to perform a post-weld heat treatment (PWHT) at a minimum temperature of 1625°F for 1.5 hours before a fabrication is put into service. Consequently, pressure vessels designed according to ASME Code made from Alloy 800H and/or 800HT/AT must undergo PWHT if they are to operate at temperatures exceeding 1000°F.

Commercial Availability

Today, most alloy 800 is dual certified as 800H/800AT or 800H/800HT. It is rare to find alloy 800 straight grade available in a quantity lower than that of a heat lot.

Comparison of Different Versions of Alloy 800

References

(2004). The story of the “INCOLOY® alloys series,” from 800, through 800H, 800HT®. Special Metals. https://doi.org/Publication Number SMC-047

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.