Home » News & Articles » Alloying Elements Explained

Their Role in Defining the Purpose and Performance of metals

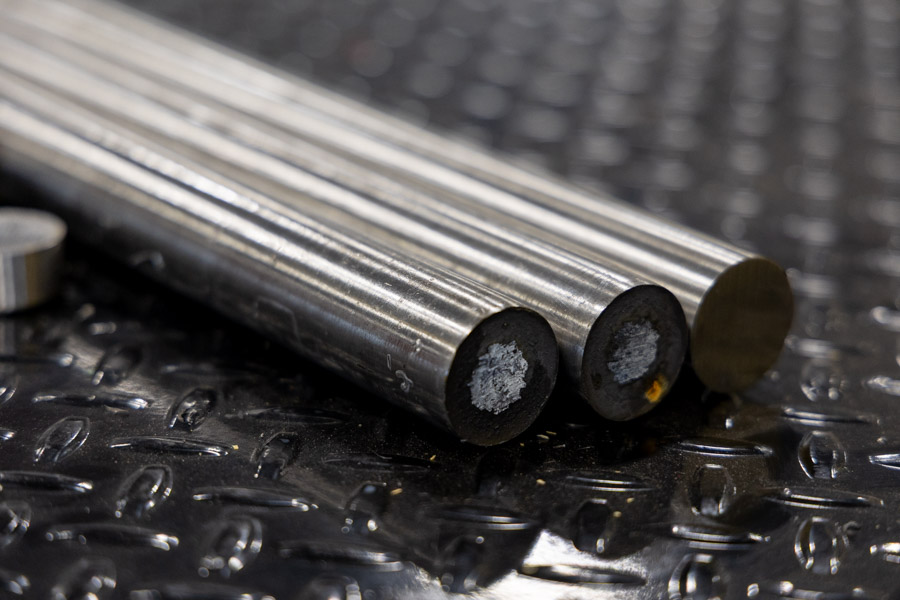

Metals are rarely used in their pure form. By adding different elements, engineers and manufacturers create alloys — combinations of metals and sometimes non-metals — to meet specific selection criteria and purposes. Understanding which elements are added to alloys and how they influence the final material’s physical, mechanical, and corrosion properties is essential when selecting the right metal for a job. In this article, we’ll break down the key elements alloyed into metals, explain the effects of adding these elements, and provide practical guidance for anyone interested in metals, alloys, and their applications.

What Are Alloying Elements?

Alloying elements are substances intentionally added to a base metal, such as iron or nickel. The primary purpose of alloying is to enhance properties like strength, ductility, corrosion resistance, or heat resistance. Alloying elements also determine what the internal structure of the metal will be, leading to various effects on performance, durability, and suitability for specialized purposes.

The Most Common Alloying Elements and Their Effects

Iron (Fe)

Iron acts as the foundation for many alloys, especially steel. Pure iron is soft and prone to corrosion, but adding other elements transforms its properties. Iron’s role is mainly as a base metal.

Carbon (C)

Carbon has a powerful effect on strengthening alloys. As carbon increases, so does strength, hardness, wear-resistance, and load-bearing capacity. However, with that increase, alloys typically become less ductile and more brittle. These changes in mechanical properties occur with slight variations in carbon content. In heat-resistant alloys, the carbon content is carefully controlled to balance strength and workability. Carbon content is minimized for corrosion-resistant alloys due to possible concerns over sensitization.

Chromium (Cr)

Chromium is one of the most critical elements in stainless steels and nickel alloys and is the essential ingredient that makes stainless steel “stainless.” Adding 10–13% chromium to alloys creates a protective, continuous oxide layer that helps mitigate rusting. For heat-resistant alloys, increasing chromium adds to both high-temperature strength and carburization resistance. For corrosion-resistant alloys, chromium increases an alloy’s resistance to chloride pitting and crevice corrosion. Chromium also boosts hardness and tensile strength, but at amounts above about 30%, it can make the metal more brittle. Due to the increase in hardness and tensile properties, workability tends to be dramatically reduced, making it impractical for wrought alloys to have chromium contents above 30%.

Nickel (Ni)

Nickel is widely used to improve ductility (the ability to deform without breaking), strength, and toughness. Nickel can also improve resistance to both corrosion and high temperatures, which is why nickel-rich alloys are commonly used in chemical plants and high-temperature applications. Nickel-rich alloys can retain much of their strength at high temperatures, often maintaining 40% to 75% of their original strength even at 2,000°F. This makes them ideal for high-heat environments such as turbines, high temperature exhaust components, and heat treating. Nickel also helps alloys resist deformation under long-term heat and stress (a property known as creep resistance) and improves resistance to acids and caustic environments.

Manganese (Mn)

Manganese is primarily used to enhance hot workability and weldability in metals. It contributes to the formation of strong, tough materials by increasing strength, hardenability, and wear resistance. Additionally, manganese reacts with sulfur, which reduces the likelihood of brittleness during processing. Alloys that contain manganese are easier to manufacture and can be shaped or machined with a lower risk of cracking. Manganese also improves nitrogen solubility and can partially replace nickel in stainless steels, making it a versatile and valuable addition in many alloys.

Molybdenum (Mo)

Molybdenum is added to alloys when extra strength and resistance to localized corrosion are needed. It boosts resistance to pitting and crevice corrosion, particularly in chloride-rich environments, and slightly increases mechanical strength and high-temperature performance. By improving strength at both room and high temperatures, molybdenum is a key element for alloys exposed to heat and mechanical stress. Molybdenum also contributes to slow grain growth, which is important in maintaining fine microstructures and thus prolonging metal life. For high-temperature service, alloys that contain a significant amount of molybdenum can suffer from catastrophic oxidation at excessively hot temperatures.

Silicon (Si)

Silicon improves oxidation and carburization resistance, especially in high-temperature applications. It can also increase strength, though too much may reduce ductility. In heat-resistant alloys, sufficient amounts of silicon can contribute to forming a protective suboxide layer that shields the metal from environmental attack. Silicon can also decrease weldability in some, not all, alloys.

Titanium (Ti), Niobium (Nb), and Vanadium (V)

These elements are strong carbide formers, which can help tie up the carbon within a material to help prevent sensitization and/or improve strength (especially at high temperatures). These elements also contribute to fine-grain size and can increase wear resistance. They are critical in specialized alloys for aerospace, power plants, and cutting tools where stability at elevated temperatures is essential.

Aluminum (Al)

Aluminum improves oxidation resistance, particularly at very high temperatures. An alloy with a sufficiently high aluminum content can form an adherent suboxide layer that can significantly enhance oxidation, carburization, and nitridation resistance. Aluminum also acts as a deoxidizer, helping to remove unwanted gases during metal production while forming intermetallic compounds that increase strength in precipitation-hardening alloys. Because of this, aluminum is used in stainless steels and high-performance nickel alloys.

Tungsten (W)

Tungsten’s addition yields high-temperature strength and hardness. It improves wear and pitting corrosion resistance and helps form stable carbides.

Copper (Cu)

Copper enhances corrosion resistance, especially in hostile environments involving seawater or specific acids. It can also improve strength and electrical conductivity.

Nitrogen (N)

Nitrogen is used to strengthen alloys and control grain size. It improves tensile and yield strength, enhances resistance to pitting corrosion, and helps prevent the formation of brittle phases. However, too much nitrogen can make the alloy brittle. In ferritic grades, nitrogen can reduce toughness and increase hardness, while reducing toughness in martensitic grades.

Sulfur (S) and Phosphorus (P)

Although generally considered impurities, small amounts of sulfur can improve machinability, while too much can cause brittleness. Phosphorus increases strength and hardness, but in excess, it harms weldability and ductility. Both elements are therefore tightly controlled when formulating alloys for optimal performance.

Rare Earth Elements: Cerium (Ce), Yttrium (Y)

Rare earth elements are used as micro-alloying additions to enhance various material properties. Cerium and yttrium are especially valuable in high-temperature environments, where they promote the formation of tightly adherent oxide scales, thereby reducing oxidation rates.

How Alloying Elements Influence Metal Selection for Purpose

Choosing the right alloy for a particular purpose involves understanding how these elements affect the final metal. For example, selecting a metal for high-temperature processing equipment might require high nickel, chromium, and aluminum contents for strength and oxidation resistance. On the other hand, marine applications would benefit from high levels of chromium, nickel, and molybdenum for corrosion resistance.

Selecting an alloy is about matching the metal’s properties to the demands of the environment and the task. The wrong choice could lead to rapid failure, while a well-chosen alloy ensures safety, durability, and efficiency, even if the initial material cost is higher.

Key Takeaways

Alloying elements are at the heart of tailoring the properties of metals for selection and purpose. By understanding what each element does, engineers and manufacturers can choose materials that deliver the right mix of strength, ductility, corrosion resistance, and durability. This knowledge leads to safer designs, longer service lives, and improved performance.

References

Kelly, J.C. “Heat Resistant Alloy.” Rolled Alloys, Temperance, MI.

Nickel Institute Technical Publication No. 10086: “Corrosion- and Heat-Resistant Nickel Alloys: Guidelines for Selection and Application” by G. Sorell, reprinted from Chemical Processing (Nov. 1997 and Oct. 1998), distributed by the Nickel Institute.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.