Home » News & Articles » 5-Axis Waterjet Beveling

What Is a 5-Axis Waterjet Cutter?

A 5-axis waterjet is an advanced CNC solution designed for high-precision metal cutting. It uses an ultra-high-pressure stream of water mixed with abrasive media – typically garnet – to cut metal accurately and efficiently.

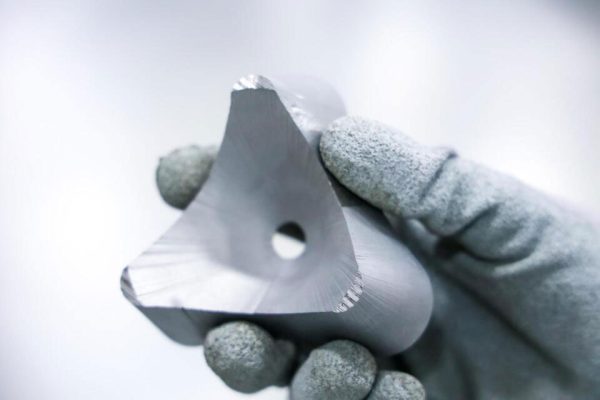

Unlike standard flat-cutting systems, a 5-axis waterjet adds controlled head rotation and tilt, allowing our machine to produce angled or beveled cuts up to a maximum of 45° in a single setup.

How It Works

The core technology is still abrasive waterjet cutting:

High-pressure pump pressurizes water (often >60,000 psi).

Water passes through a tiny opening to create a supersonic jet.

Abrasive grit (e.g., garnet) is added at the nozzle to cut harder metals.

The cutting head tilts and rotates to maintain accuracy when producing bevels up to 45°.

Because waterjet cutting is a cold cutting process, it doesn’t introduce heat-affected zones, preserving the material’s structural properties – a major advantage over plasma or laser cutting on heat-sensitive alloys.

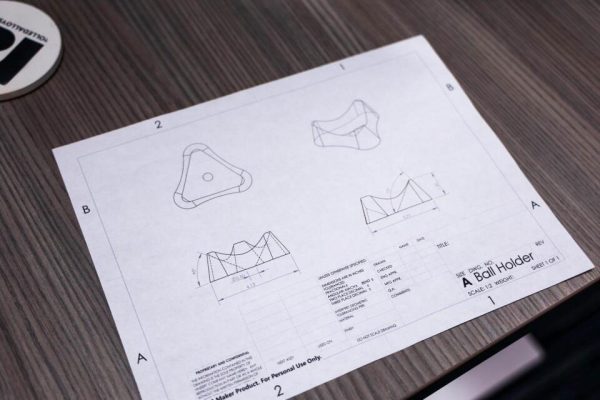

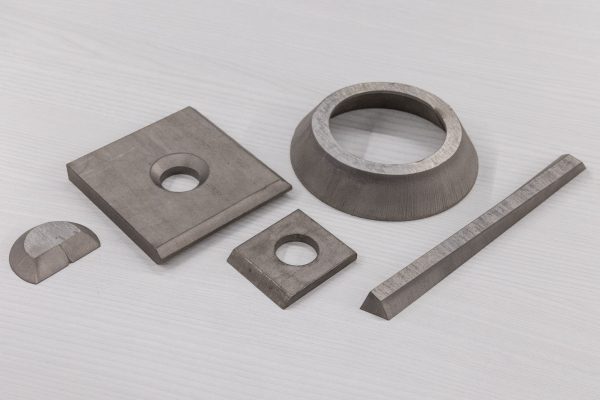

Examples of 5-Axis waterjet beveling & capabilities.

Key Advantages

Precise Bevel Cutting (Up to 45°)

The added rotational axes allow for consistent, accurate bevels up to 45°, making parts suitable for welding, assembly, or structural applications without additional edge preparation.

No Heat Distortion

Since no heat is applied during cutting, there is no warping, micro-cracking, or metallurgical change, even on heat-sensitive alloys.

Reduced Secondary Operations

Integrated beveling eliminates the need for post-cut grinding, machining, or manual edge prep – saving time and reducing labor costs.

Material Versatility

5-axis waterjet systems can cut a wide range of metals, including:

Thickness capabilities vary by material and pump power but can range from thin gauge metals to several inches thick.

Tolerances & Beveling Capabilities

- .015″ to 1/2″ thick: +/- .030″

- > 1/2″ to 2″ thick: +/- .045″

- > 2″ to 3″ thick: +/- .090″

- > 3″ to 3 1/2″ thick: +/- .125″

- 4″ to 4 1/2″ thick: +/- .1875

- > 4 1/2″ thick: +/- .25

- The waterjet bed size is 72″ x 144″ & 120″ x 240″

- Beveling capability up to 45°

Diagonal squareness 3/16″ for cut rectangles/squares

Drawings in .dxf or .dwg format are preferred. Other acceptable formats include .iges and .pdf files.

Cutting up to 6″ thick material for straight cuts and 1 1/2″ for bevels.

Select your preferred Processing when Creating a Quote

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.