March Mania 2025

Every Online Order in March is a Chance to Win One of 8 Great Prizes!

Instant Pricing on Nickel, Stainless Steel, Duplex, and Titanium

Get real-time pricing and availability for nickel, stainless steel, duplex, and titanium—all in one place.

New and Expanded Stock for 2025

New Titanium, Stainless, Nickel and Cobalt in Stock Now – CP Ti Grade 2, 635, 718 and More!

New Bar Stock Available

New Round and Flat Bar Products in Stock at Rolled Alloys

Los Angeles Operations Tour

Los Angeles Operations Tour with General Manager Carol Plana Back To All Articles Share: Quote, Buy, Track! We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy! […]

Ground Breaking on New Manufacturing Facility in Monclova Township

Rolled Alloys commenced construction on a new high-tech manufacturing facility in Monclova Township, near Toledo

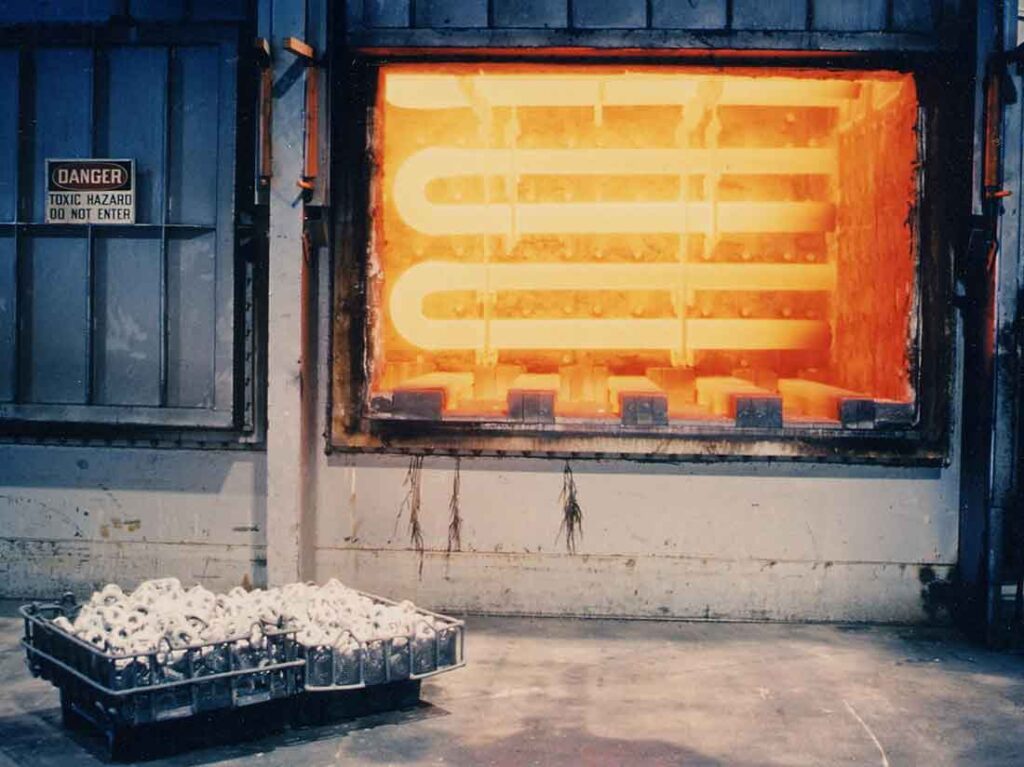

70 years in the Thermal Processing Industry

Over the past 70 years, we have been committed to servicing the thermal processing industry. In 1953, the year Rolled Alloys was founded, we introduced RA330 as a wrought replacement to cast HT. Due to RA330’s versatility and availability, it remains the most widely used wrought alloy by commercial heat treaters.