Welding Consumable Designations and Selection Criteria

Understanding welding consumable designations is essential for achieving strong, reliable welds. This guide breaks down AWS standards, electrode naming conventions, and key factors like polarity, base materials, and welding position to help you choose the right filler metal every time.

History and Uses of Alloy 800

Discover the evolution of Alloy 800, from its origins during the 1950s to modern derivatives like Alloy 800H/800HT. Learn about its high-temperature strength, petrochemical applications, and commercial availability today.

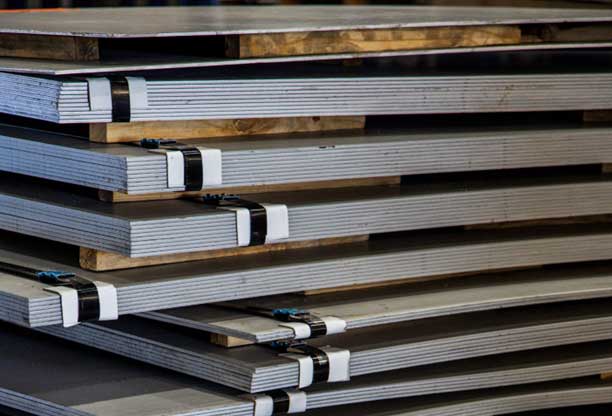

Reasons Why Duplex Stainless Steels are Replacing the 300 Series

Explore the four key benefits of duplex stainless steel: high strength, superior corrosion resistance, ease of fabrication, and cost-effectiveness. Understand why 2205 is favored over 304/304L and 316/316L for industrial applications.

Understanding P-Numbers and F-Numbers in Welding

P-Numbers and F-Numbers are essential classifications in the welding industry, particularly for projects that follow ASME codes and…

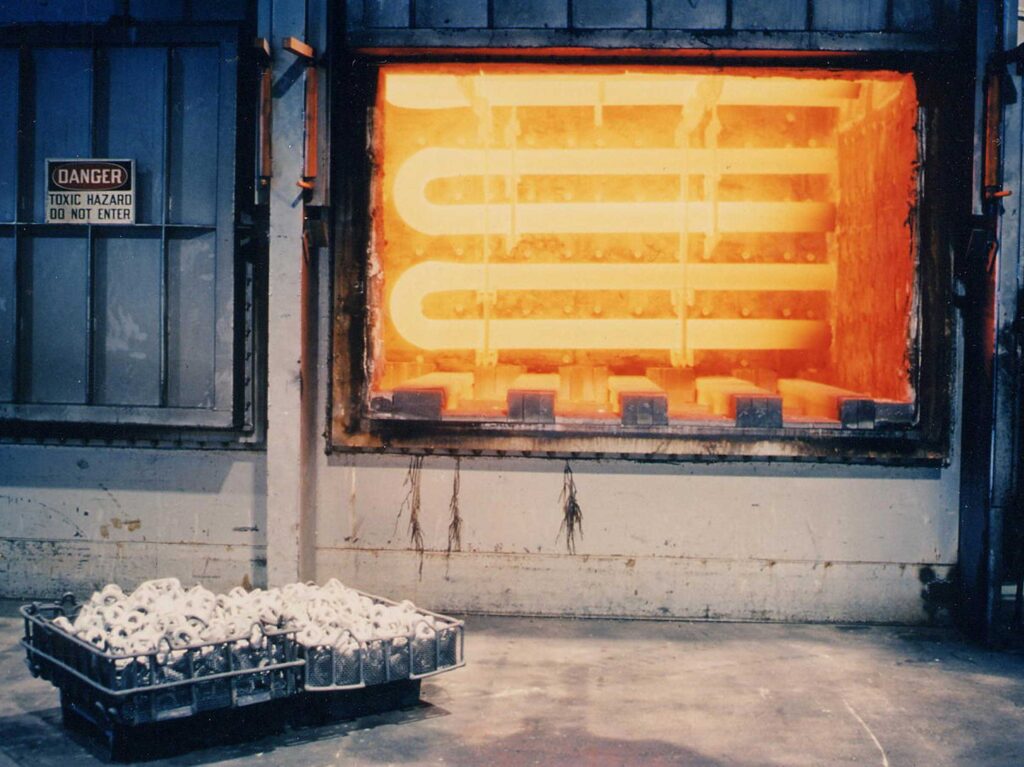

High Temperature Strength – An Explanation of Creep and Rupture

Learn how metal strength at high temperatures differs from room temperature in this comprehensive guide. Discover the importance…

Positive Material Identification (PMI)

Learn about the latest advancements in Positive Material Identification (PMI) from portable XRF to OES instruments. Understand their…

The History and Uses of AL-6XN®

AL-6XN® was developed to improve the corrosion resistance of AL-6X in seawater environments, offering better performance in resisting…

Bar Products: Specifications, Key Processes, and Common Confusions Explained

When delving into the intricacies of bar products, specific terms, processes, and even specifications are common areas of misunderstanding.

Chloride Stress Corrosion Cracking (CSCC) in Indoor Swimming Pools

Explore the causes and solutions for chloride stress corrosion cracking (CSCC) in 300 series stainless steels used in indoor swimming pool environments.

What Are Raw Material Surcharges?

The raw material surcharge offsets fluctuating costs of stainless steel and nickel alloys, calculated per pound.