Home » News & Articles » Confused About Annealing and Heat Treating Terminology?

In the broadest sense, annealing is the process of heating an alloy to an elevated temperature to promote homogenous chemistry, equiaxed microstructure, and uniform mechanical properties to produce what is essentially stress-free, or “soft” material.

In the stainless steel, nickel, and titanium alloy industries, the terms anneal, solution anneal, and solution heat treatment, are used interchangeably. Alloys of these materials are composed of multiple alloying elements and are solid solutions. By heating these materials to their solution annealing temperatures, all constituents return to a solid solution. In most instances, these elements will not remain in solution as the alloy cools, which is why most materials need to be quenched or rapidly cooled to minimize re-precipitation of carbides or other secondary phases.

The proper method of annealing – temperature, time, and rate of cooling – depends on the type of alloy. Most austenitic stainless steels are annealed at a minimum temperature of 1900°F (1040°C) followed by water quenching or rapid cooling. Martensitic steels are annealed at lower temperatures (approximately 1400°F / 760°C) and are slowly cooled.

Most martensitic steels are used in thermally hardened conditions. This is accomplished by heating annealed material to a much higher temperature (1950°F / 1065°C) and quenching as rapidly as possible. This is a hardening treatment, not annealing. To improve toughness, these alloys are then tempered by re-heating in the range of 300°F – 1000°F (150°C – 530°C).

Alloys that are stabilized using titanium or niobium to prevent chromium carbide precipitation can be supplied either solution annealed or stabilize annealed. This group of materials includes alloys such as 321, 347, Alloy 20, and 625. Solution annealing these alloys involves heating them to at least 1850°F (1010°C) to place the constituents into a solid solution. Stabilize annealing is performed at a lower temperature, usually around 1650°F – 1750°F (900°C – 950°C), to intentionally force the formation of titanium or niobium carbides. Types 321 and 347 are typically supplied in the solution annealed condition and arrangements for stabilized annealed material must be made as a separate procedure. Alloy 20 specifications call for it to be supplied in the stabilized annealed condition. 625 is also commonly supplied in the stabilized annealed condition (Grade 1) but can be ordered and supplied in the solution annealed condition (Grade 2).

Thermal hardening or strengthening of some alloys is accomplished by precipitating secondary phases. This group of materials includes alloys such as 17-4PH, 15-5PH, 13-8PH, A-286, and 718. The thermal hardening process can be identified as precipitation hardening, age hardening, or precipitation heat treatment. Age hardening temperatures and times vary with the alloy and the desired properties but are generally carried out at temperatures between 900°F – 1450°F (480°C – 790°C). The precipitation heat treatment is more commonly carried out after all machining, welding, and/or forming is completed.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

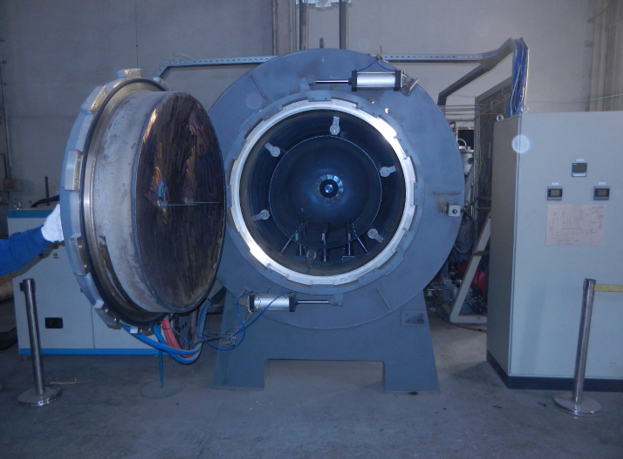

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.