Home » News & Articles » How the Kroll Process Produces Titanium Sponge

Transforming Titanium Ore into Pure Titanium Sponge

Introduction

The Kroll process is the primary industrial method for transforming titanium ore into metallic titanium. It enables the production of high-purity metal, which serves as the foundation for high-performance titanium alloys. Since its development in the mid-20th century, the process has made titanium widely available for critical applications in aerospace, medical technology, and chemical processing.

What Is The Kroll Process?

The Kroll process is a multi-step chemical procedure developed by William J. Kroll in the 1940s. It is designed to extract pure titanium metal from naturally occurring ores like rutile. This process consists of several carefully controlled stages that remove impurities, ensuring the production of high-purity titanium.

Step-by-Step: How The Kroll Process Produces Titanium Sponge

- Converting Titanium Ore to Titanium Tetrachloride

The conversion process begins with titanium ore, primarily rutile. Once the ore is collected, it is placed into a specialized apparatus known as a chlorinator. Here, ore is reduced with the introduction of coke and treated with chlorine gas at high temperatures. When chlorine gas is introduced, it reacts with titanium to generate titanium tetrachloride, a colorless and volatile liquid with a distinctive, pungent odor. This step isolates titanium from oxygen and effectively removes various impurities, producing a purified form of titanium in its chlorinated state.

- Purification of Titanium Tetrachloride

The crude titanium tetrachloride is accompanied by various undesirable byproducts that can affect its purity. To achieve a high level of refinement, the titanium tetrachloride undergoes a process known as fractional distillation. This technique leverages the differences in boiling points to effectively separate TiCl₄ from its impurities, allowing the more volatile titanium tetrachloride to rise through the distillation column. As a result, a highly purified form of titanium tetrachloride is obtained, ensuring it is ready for the subsequent processing stages. Fractions close to titanium are further separated by precipitation.

- Reduction to Titanium Sponge

The purified titanium tetrachloride is meticulously transferred to a sealed reactor, where it is combined with molten magnesium. This process occurs at extremely high temperatures and reduces titanium tetrachloride to pure titanium metal.

The outcome of this reaction is the production of a porous, sponge-like form of titanium metal, known as titanium sponge. Additionally, magnesium chloride is generated as a byproduct of the reaction, which can be further processed or reused.

- Purification of Titanium Sponge

After initial processing, the titanium sponge retains some residual magnesium and magnesium chloride. These impurities are eliminated by leaching with a suitable acid or vacuum distillation to purify it. This process effectively vaporizes the unwanted materials while preserving the integrity of the titanium.

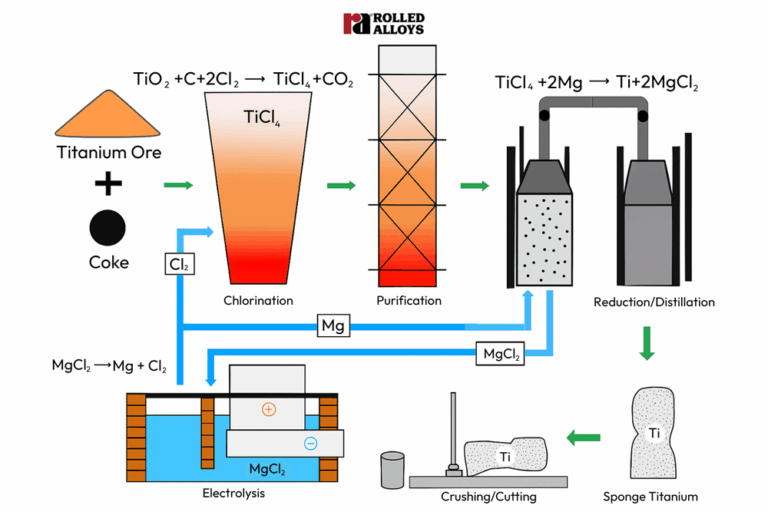

The Kroll Process Step-by-Step: Diagram and Explanation

- Ore Preparation: Titanium ore, most commonly rutile, is mixed with coke.

- Chlorination: At high temperatures, coke reduces the ore, and chlorine gas produces TiCl₄.

- Distillation: TiCl₄ is purified through fractional distillation and precipitation.

- Reduction: TiCl₄ is reduced with molten magnesium in a sealed reactor to create titanium sponge.

- Purification: Byproducts are removed from the titanium sponge through leaching or distillation.

Figure 1: Step-by-Step of the Kroll Process

Why the Kroll Process Matters: Advantages and Challenges

Advantages

- High Purity: The Kroll process yields titanium metal of exceptional purity, essential for aerospace, medical, and industrial uses.

- Versatility: Titanium produced by this method can be melted into ingots that can be formed into sheets, plates, bars, and forgings for a wide range of industries.

Challenges

- High Cost: Although titanium ore is abundant, the Kroll Process is slow and energy-intensive, making titanium much more expensive than metals like steel.

- Yield: The process operates in discrete batches rather than a continuous flow, limiting throughput and efficiency.

- Reactivity: Titanium’s tendency to absorb impurities means the process must be carefully controlled, adding to cost and complexity.

Conclusion

Today, the Kroll process is the most efficient method for transforming titanium ore into pure titanium sponge. While it is energy-intensive and involves complex steps, no other process comes close to that of the Kroll process when it comes to efficiently making titanium sponge on a commercial scale.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.