Home » News & Articles » Introduction to Heat Resistant Alloys

We have been supporting the heat-resistant alloy market for over 70 years. Many different industries, such as thermal processing, chemical processing, and power generation, depend on the capabilities of these alloys to perform day-to-day activities.

In this webinar, we will explore the world of wrought heat-resistant alloys. The listener will be introduced to commonly utilized heat-resistant alloys, factors to consider when selecting a heat-resistant alloy, and some industrial applications within specific industries.

Presentation Slides

Exploring the World of High-Temperature Alloys

Welcome to Rolled Alloys’ Webinar Series

Hello and welcome to Rolled Alloys’ second webinar in our ongoing series. In today’s session, we’re delving into the fascinating world of heat-resistant alloys. Whether you’re a materials enthusiast or someone seeking specific solutions for high-temperature applications, we’ve got you covered.

In this blog post, we will cover key takeaways from the webinar, explore the fundamental aspects of heat-resistant alloys, and discuss their applications. We will also touch upon some important considerations when choosing the right materials for your specific needs.

Rolled Alloys: Your Trusted Global Supplier

Before we dive into the world of heat-resistant alloys, it’s essential to know who we are. Rolled Alloys is a global supplier specializing in high-performance alloys. Our offering includes state-of-the-art material processing, an exceptional e-commerce platform, and a team of metallurgical experts to assist you. We provide a wide range of alloys, including nickel alloys, stainless steels, duplex, titanium, cobalt, and various forms such as plates, sheets, and bars.

What are Heat-Resistant Alloys?

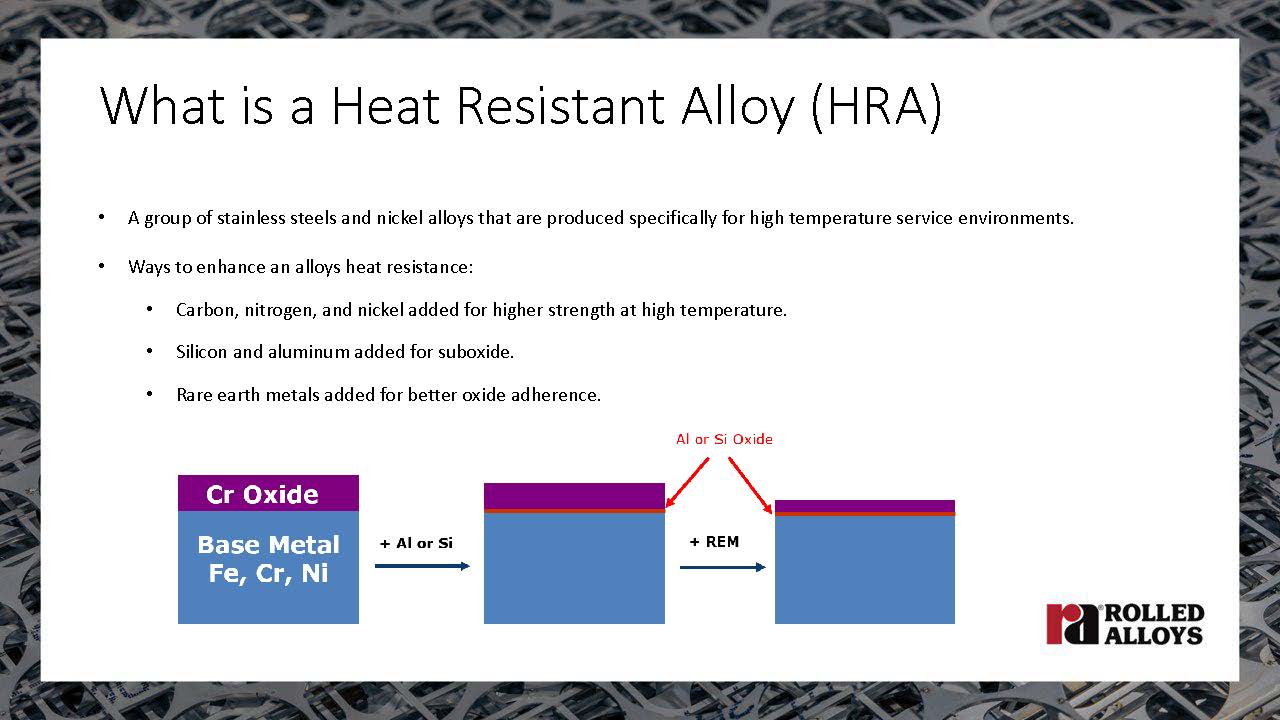

Heat-resistant alloys are a special group of materials designed for high-temperature environments. These alloys contain a minimum of 12% chromium to form a protective chromium oxide layer at high temperatures. Additional elements such as carbon, nitrogen, nickel, silicon, and aluminum enhance their properties. Rare earth metals are also incorporated to improve oxide adherence.

Some common heat-resistant alloys include,

Factors to Consider When Selecting Heat-Resistant Alloys

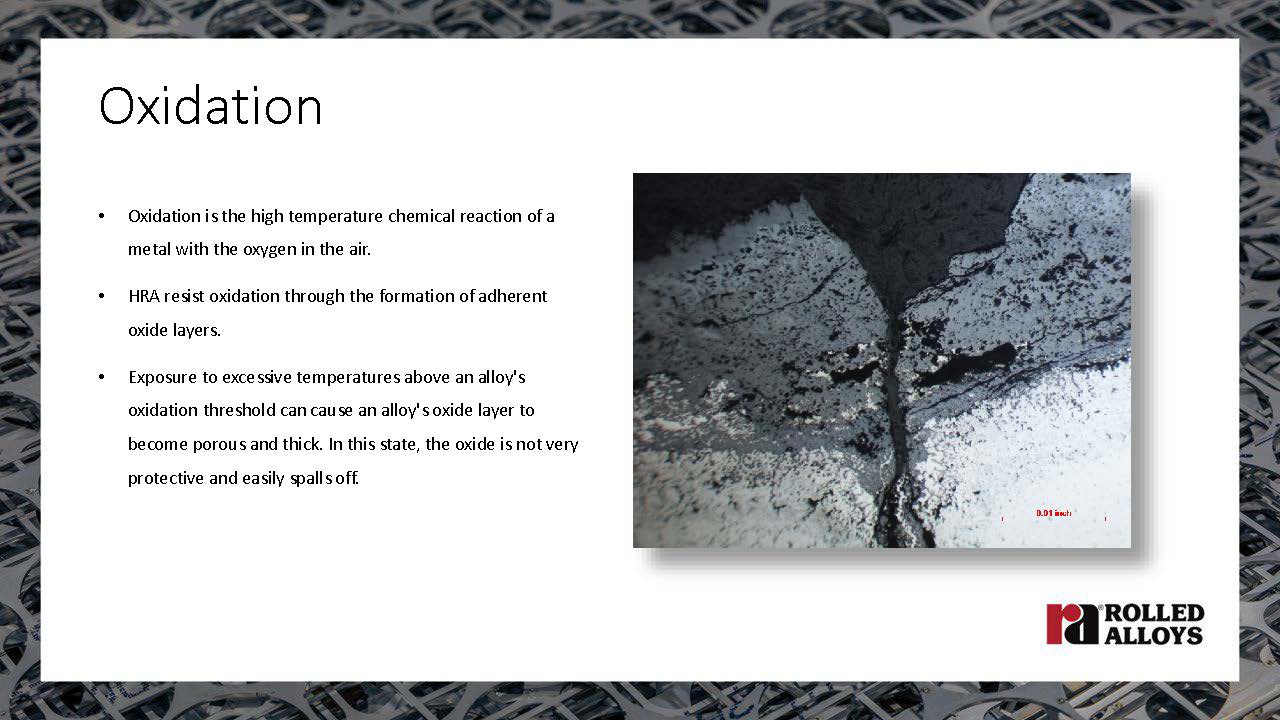

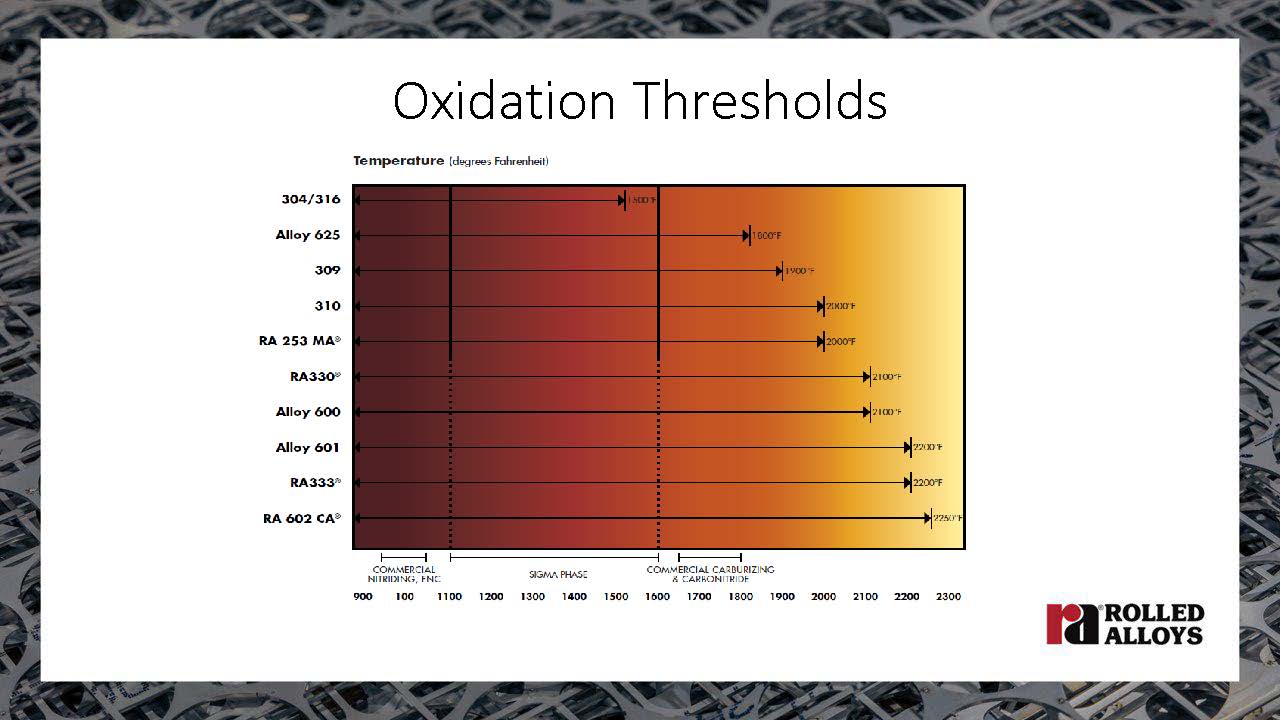

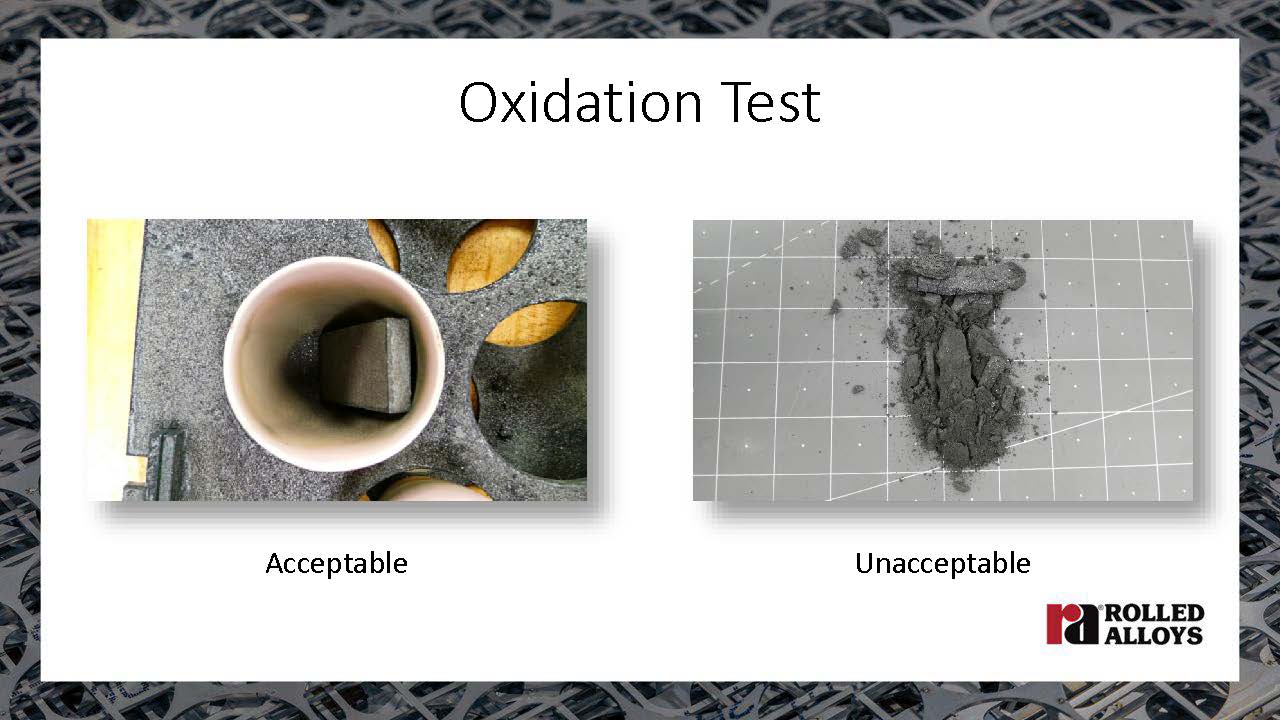

- Oxidation Resistance: Heat-resistant alloys with at least 12% chromium can form an oxide layer that protects them at high temperatures. Beyond the oxidation threshold, they become porous and brittle.

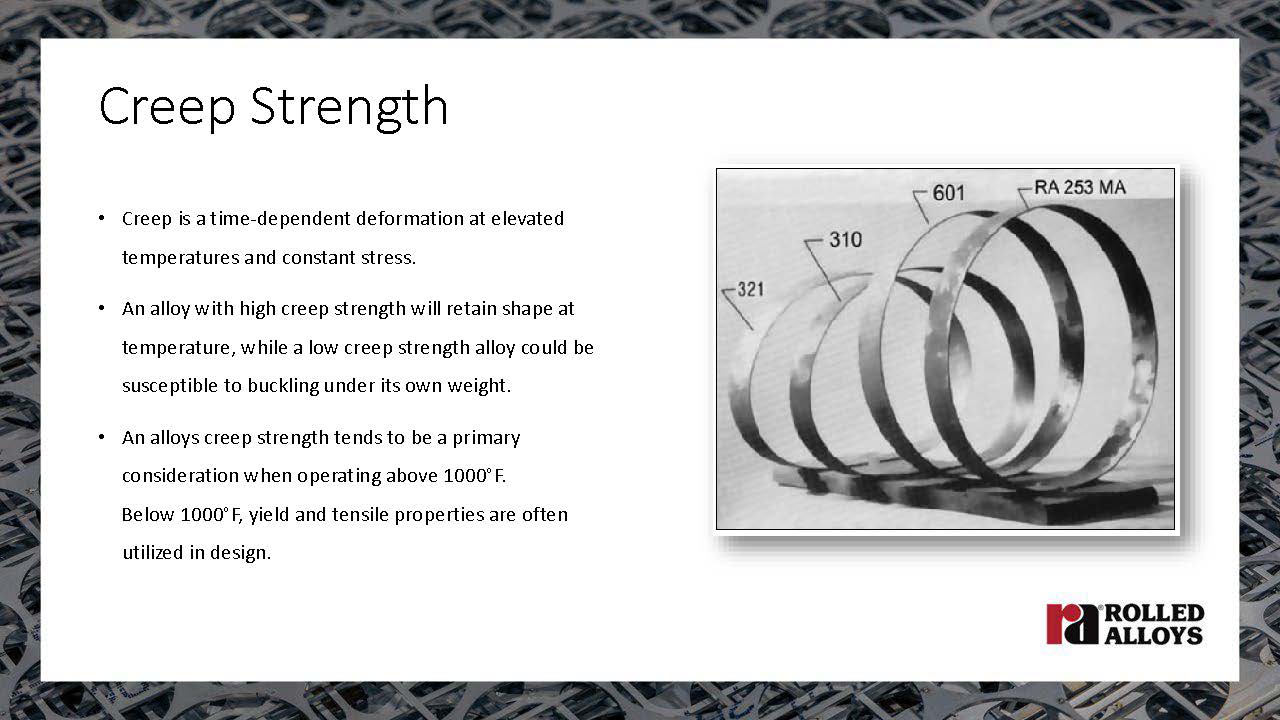

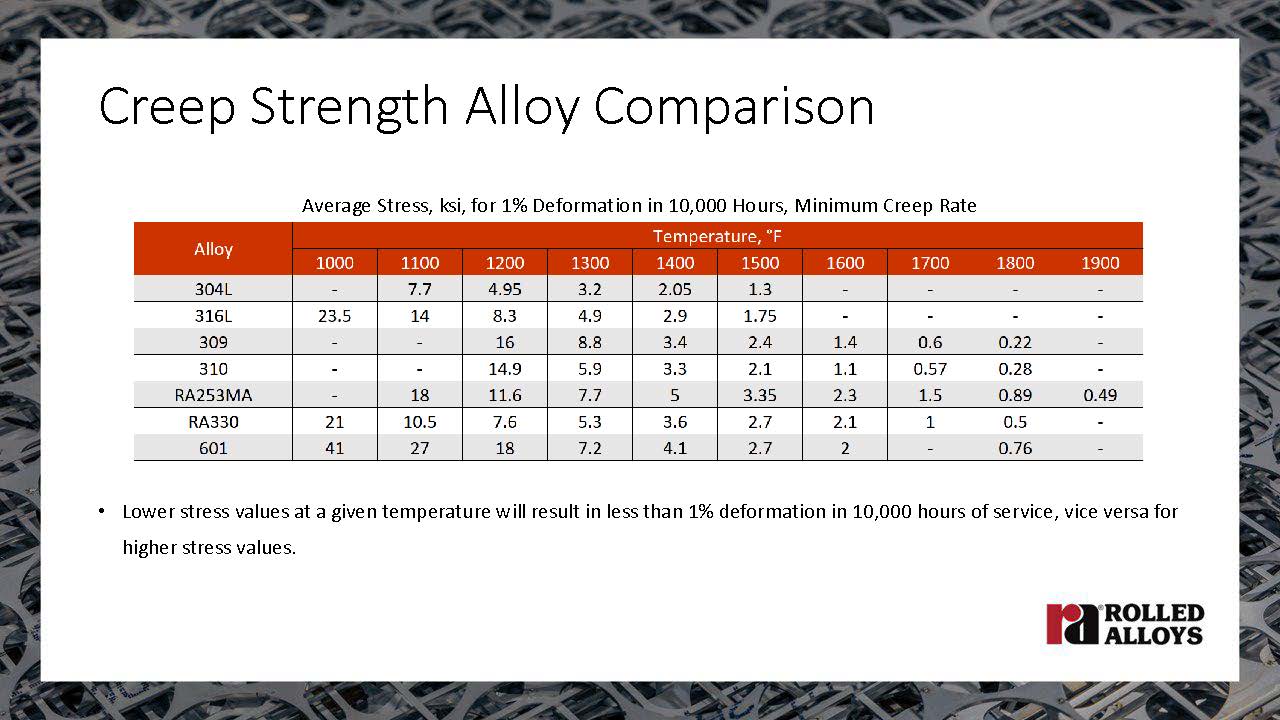

- Creep Strength: Creep is time-dependent deformation at elevated temperatures and constant stress. High creep strength alloys retain their shape, making them ideal for high-temperature applications.

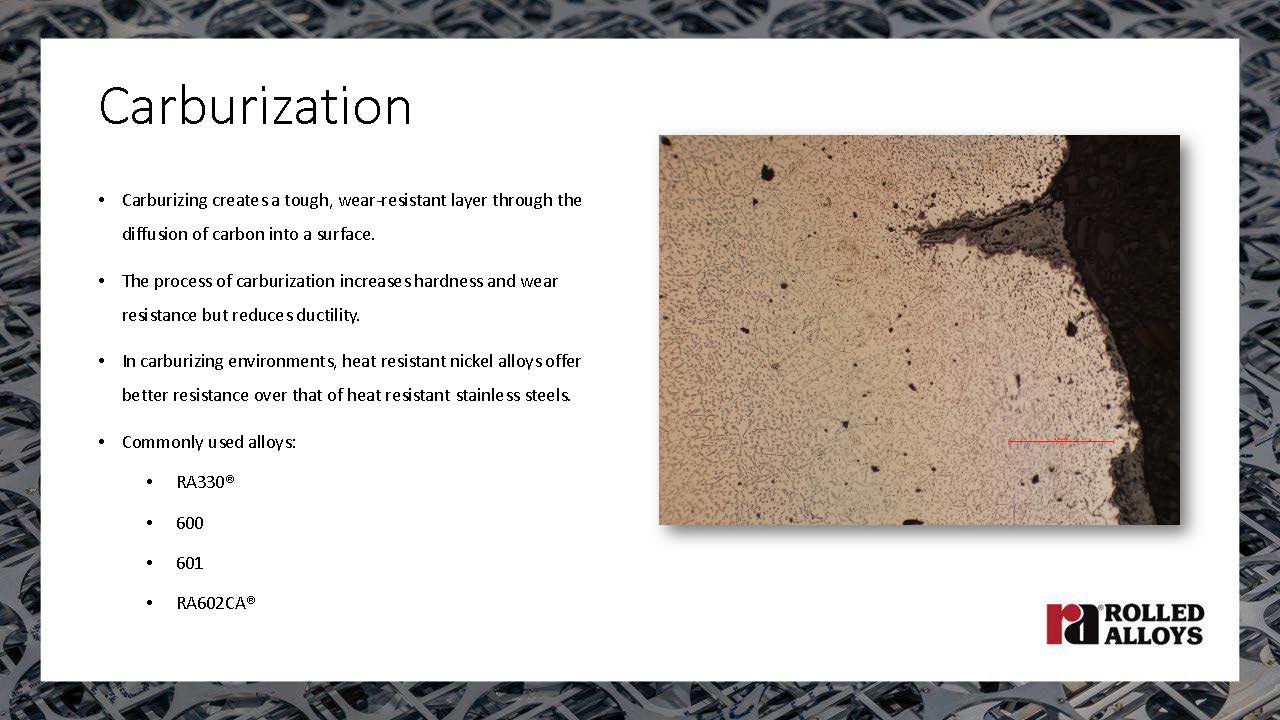

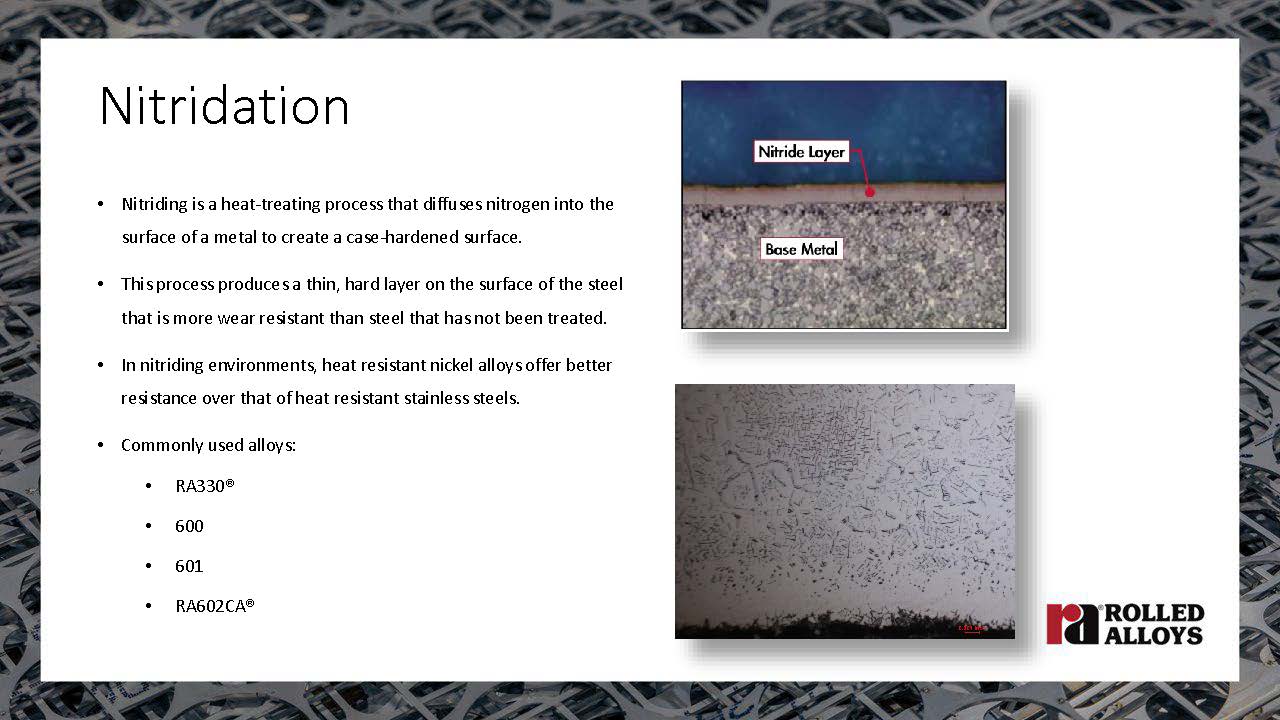

- Carburizing and Nitriding: These processes introduce carbon and nitrogen into the material’s surface, enhancing wear resistance. Alloys with high nickel content are better suited for these environments.

- Vacuum Processing: The process environment should be void of oxygen. Therefore, high temperature oxidation does not tend to be a concern.

Common Applications of Heat-Resistant Alloys

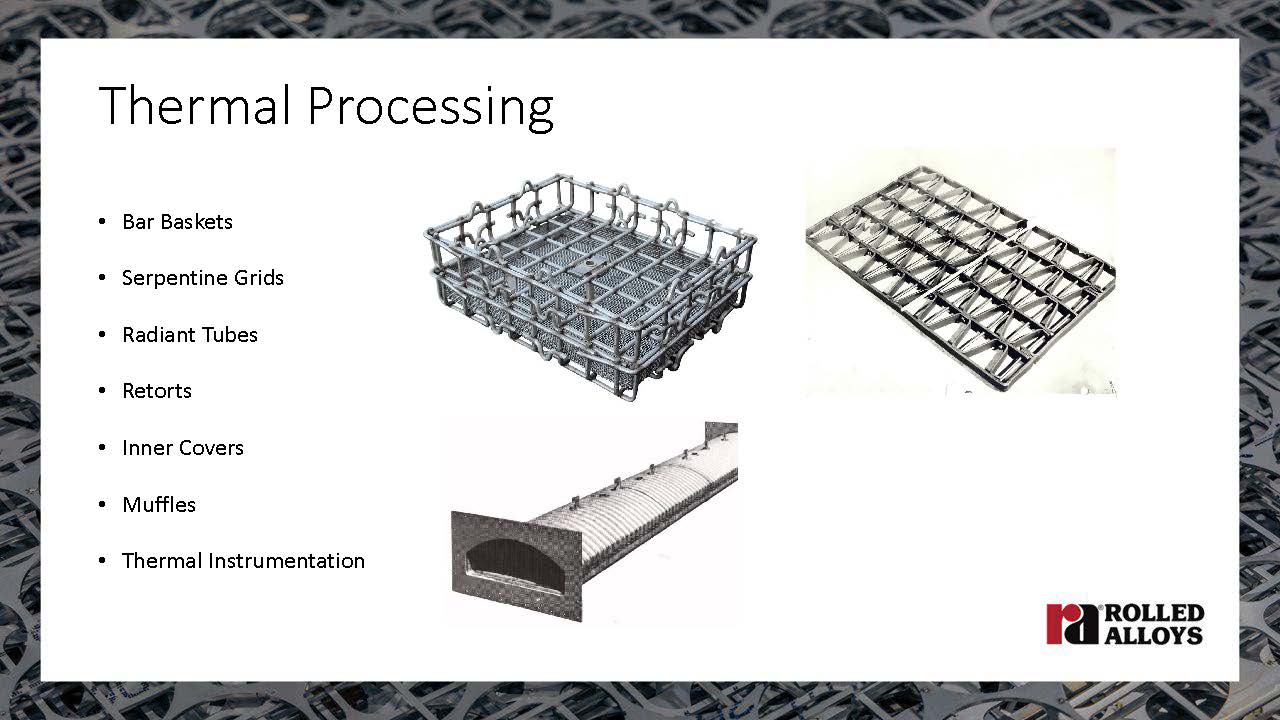

- Thermal Processing: Used for bar baskets, serpentine grids, radiant tubes, and retorts.

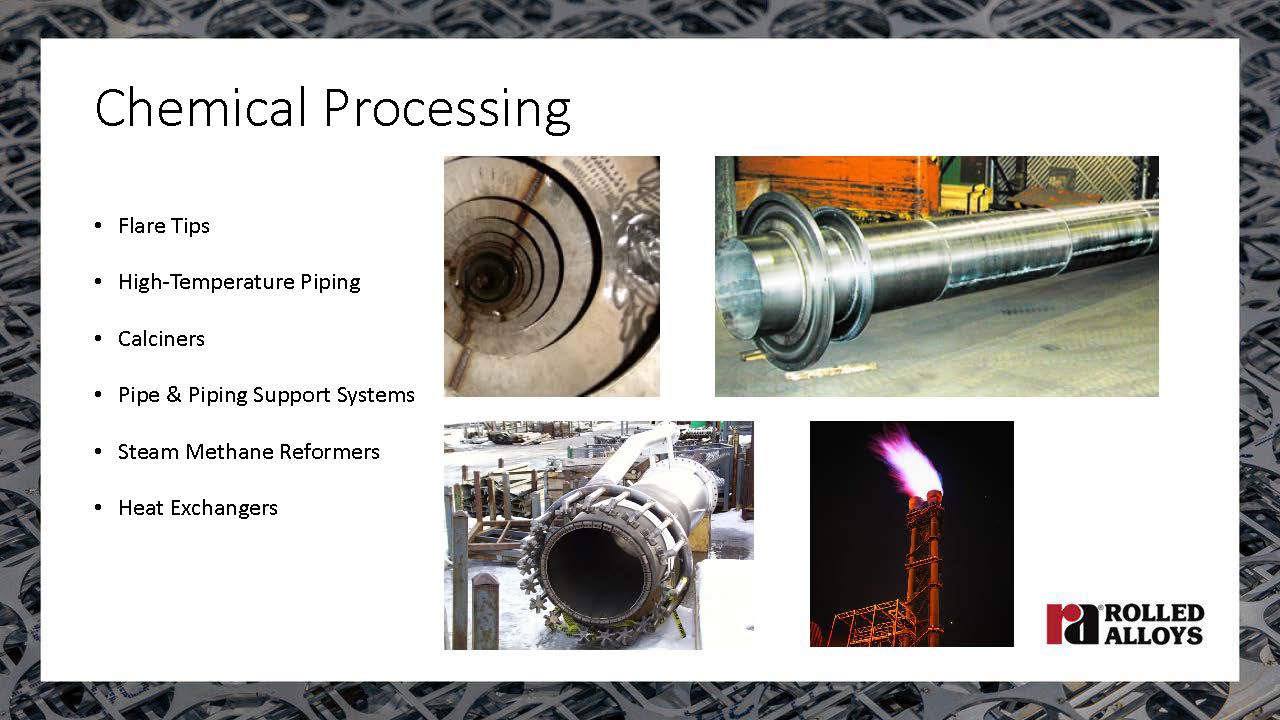

- Chemical Processing: Used for flair tips, piping, steam methane reformers, and heat exchangers.

- Galvanizing Lines: Used for their corrosion resistance.

Heat-resistant alloys are also used in a wide range of industries including:

- Power Generation

- Aerospace

- Oil and Gas

- Steel Manufacturing

Conclusion

Heat-resistant alloys are at the heart of numerous high-temperature applications. Understanding their properties and how they behave in various environments is crucial to making the right material selection.

We hope this blog post has provided you with valuable insights into the world of heat-resistant alloys. If you have any questions or need further assistance, please don’t hesitate to reach out to us. You can contact us via email or phone, and we’ll be happy to help. 1-800-521-0332 or email us: metallurgical-help@rolledalloys.com

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

AL-6XN Case Study

AL-6XN® Case Study AL-6XN® Resisted corrosive environments at indianapolis power and light for over 5 years Specifications UNS: N08367 ASTM: B 688, A

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.