Home » News & Articles » Material Test Reports

Understanding material test reports (MTR) can be challenging for those who seldom need to interpret them. There is no standard format for reporting the required information on an MTR, which leads to mills generating MTRs with varying formats. In some cases, mills indicate their ability to modify their MTR format is limited because of internal system constraints. Although MTRs vary in appearance based on the producing mill, there are commonalities.

Please contact the Rolled Alloys Metallurgical Services group at 1-800-521-0332 or email us metallurgical-help@rolledalloys.com if you have additional questions.

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

AL-6XN Case Study

AL-6XN® Case Study AL-6XN® Resisted corrosive environments at indianapolis power and light for over 5 years Specifications UNS: N08367 ASTM: B 688, A

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

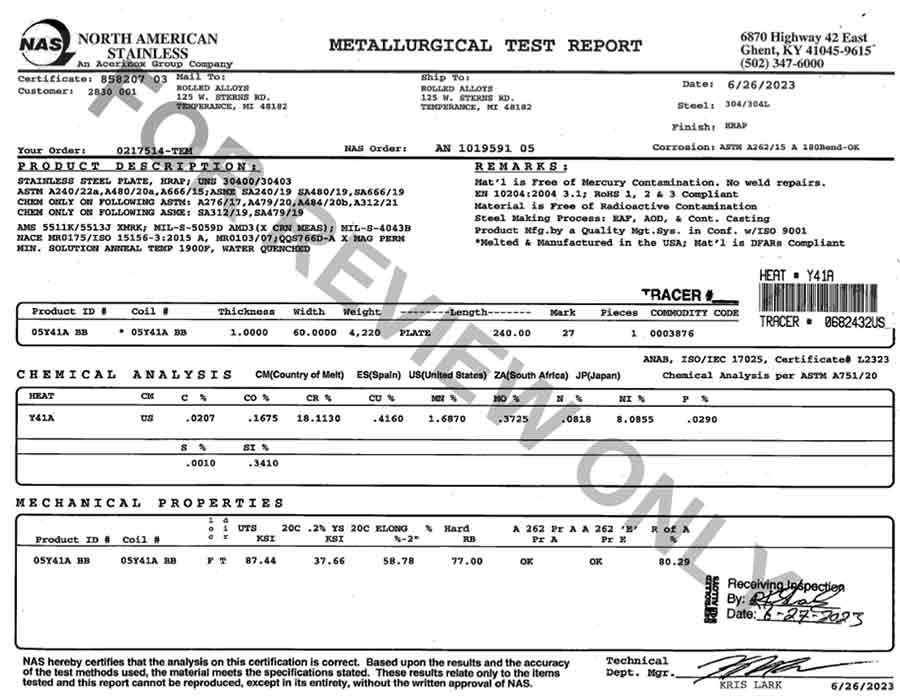

Each MTR should have a section identifying the alloy, heat number, specification(s), product form, size, and condition. Unfortunately, the reported condition does not always translate into a clear understanding of what is being supplied. For example, cold finished and cold worked may sound similar but mean different things.

An MTR will also have a chemistry section reporting the ladle analysis of the heat. A second chemistry may also be reported as a check or product analysis. It is common for melt practices to be found in an MTRs chemistry section. On many MTRs, mills will use different abbreviations for different melt practices. Common abbreviations that may be encountered include:

Occasionally, an MTR may report residual elements that are not required to be analyzed. This is permitted and does not mean there is something present that shouldn’t be.

Another section of the MTR will show mechanical properties. The information reported will vary by alloy and by specification requirements. In most instances, an MTR will indicate yield strength (0.2% YS), ultimate tensile strength (UTS), elongation (E%), hardness, and reduction of area (RA%). Some materials require Charpy impact toughness testing if they are known to undergo a ductile-to-brittle transition at low temperatures.

For thermally hardenable materials, an MTR will contain a capability testing section. Capability testing involves taking samples of the supplied material and heat-treating them, often to a specific specification’s requirements, to demonstrate the materials’ ability to achieve the required properties. For martensitic grades (410, 416, 420, 440C), the capability section often contains a hardness reading. For precipitation hardenable grades (17-4, 15-5, 13-8), aged room temperature tensile properties will be listed. Some thermally hardenable materials like 718 will require elevated temperature capability testing. This can involve elevated tensile tests as well as stress rupture testing. At elevated temperatures, loads below the yield strength can cause materials to elongate and fail over time. These tests may take several days to complete, and the results are usually reported in hours to failure. More than one set of properties may be reported if testing is done to more than one specification. The results will generally be distinguished by the heat treatment parameters used to determine the capability. Remember that capability test results are from heat-treated samples and do not represent the supplied condition.

Depending on the specification purchased to or purchase order requirements, MTRs may report grain size, results of corrosion testing, magnetic properties, and more. With so many different styles, languages, and terms, even veteran metallurgists may need extra time to decipher the results of an MTR. If you need help understanding an MTR, don’t hesitate to contact Rolled Alloys Metallurgical Services or QA.