Home » News & Articles » RA 253 MA® vs 309/310

RA 253 MA® Advantages Against 309/310: Overview

The main difference between RA 253 MA and both 309 and 310 stainless steel lies in alloy composition and resulting high‑temperature performance. RA 253 MA contains micro‑alloy additions of cerium, silicon, and nitrogen, which enhance oxidation resistance and creep strength at elevated temperatures. In addition, RA 253 MA has a lower overall nickel and chromium content, making it less susceptible to fluctuations in commodity pricing when compared to 309 and 310 stainless steels.

Key Differences and Comparisons

- Alloying Elements and Cost Stability

RA 253 MA includes additions of cerium, silicon, and nitrogen, while also having lower nickel and chromium content than 309 and 310 stainless steel. This lower alloy content makes RA 253 MA less vulnerable to fluctuating commodity prices. Oxidation Resistance

The micro‑alloy addition of cerium, along with silicon, provides RA 253 MA with good oxidation resistance up to 2000°F. This performance is comparable to 310 stainless steel and superior to 309 stainless steel.Creep Strength at High Temperatures

Due to the combined additions of carbon and nitrogen, the creep strength of RA 253 MA is more than twice that of both 309 and 310 stainless steel at temperatures above 1600°F.ASME Pressure Vessel Approval

RA 253 MA is approved under ASME Section VIII, Division 1 for pressure vessels up to 1650°F. In contrast, 309 and 310 stainless steels are only approved up to 1500°F.ASME P-Group Classification

RA 253 MA, 309, and 310 are all assigned to the same P‑Group in ASME Section IX: P‑Group 8, Group 2.Welding Consumables for Matching Strength

RA 253 MA is welded using RA 253 MA matching composition weld filler, available from Rolled Alloys in FCAW, GTAW, GMAW, and SMAW forms.Dissimilar Metal Welding

RA 253 MA can also be welded to other 300‑series stainless steels using RA 253 MA weld filler, or to higher‑nickel alloys using RA 333 weld filler, to maintain weld strength similar to the RA 253 MA base metal.Product Availability

Rolled Alloys stocks a complete range of RA 253 MA products, including plate, sheet, round bar, pipe, and welding consumables.

Chemical Composition %

| | Cr | Ni | Si | Mn | N | C | Ce | Fe |

|---|---|---|---|---|---|---|---|---|

| RA 253 MA® UNS S30815 | 21.0 | 11.0 | 1.7 | 0.6 | 0.2 | 0.08 | 0.04 | balance |

| 310 UNS S31008 | 25.0 | 20.0 | 0.5 | 1.6 | -- | 0.05 | -- | balance |

| 309 UNS S30908 | 23.0 | 13.0 | 0.8 | 1.6 | -- | 0.05 | -- | balance |

Creep-Rupture Properties

Minimum Creep Rate 0.0001% Per Hour

Stress to Rupture 10,000 Hours

Creep Test

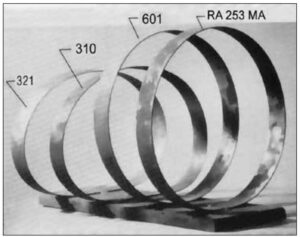

Ring specimens subjected to a temperature of 1800°F under the stress of their own weight for a total of 32 hours.

See Figure to Left

Typical Tensile Properties, Plate

| | Temperature | 70°F | 1200°F | |

|---|---|---|---|---|

| RA 253 MA® | Ultimate Tensile Strength, | ksi | 87 | 56.4 |

| 0.2% Offset Yield Strength | ksi | 45 | 23.0 | |

| 310 | Ultimate Tensile Strength, | ksi | 75 | 54.1 |

| 0.2% Offset Yield Strength | ksi | 30 | 20.7 | |

| 309 | Ultimate Tensile Strength, | ksi | 75 | 52.0 |

| 0.2% Offset Yield Strength | ksi | 30 | 22.0 |

ASME Section VIII Div. 1 Maximum Design Allowable Stresses

| Temperature | °F | 1100 | 1200 | 1350 | 1500 | 1650 |

|---|---|---|---|---|---|---|

| RA 253 MA® | ksi | 9 | 5.2 | 2.4 | 1.3 | 0.71 |

| 310H | ksi | 7.6 | 4 | 1.7 | 0.75 | -- |

| 309H | ksi | 7.6 | 4 | 1.4 | 0.75 | -- |

309H and 310H are only approved to 1500°F. Values for 309H and 310H are used in this comparison as they have higher values than 309 and 310 straight grade.

Maximum Suggested Temperature Limit in Air

2000°F Cyclic Oxidation Testing in Air

Contact Us!

AL-6XN® Case Study

Coal-fired power plants generate flue gas as a byproduct of combustion. In many modern plants, especially those burning coal with high sulfur and chloride content,

RA 253 MA® vs 309/310

The main difference between RA 253 MA and both 309 and 310 stainless steel lies in alloy composition and resulting high‑temperature performance. RA 253 MA

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

AL-6XN® Case Study

Coal-fired power plants generate flue gas as a byproduct of combustion. In many modern plants, especially those burning coal with high sulfur and chloride content, this flue gas can become highly corrosive to carbon steel and even conventional stainless steels.

RA 253 MA® vs 309/310

The main difference between RA 253 MA and both 309 and 310 stainless steel lies in alloy composition and resulting high‑temperature performance. RA 253 MA contains micro‑alloy additions of cerium, silicon, and nitrogen, which enhance oxidation resistance and creep strength at elevated temperatures. In addition, RA 253 MA has a lower overall nickel and chromium content, making it less susceptible to fluctuations in commodity pricing when compared to 309 and 310 stainless steels.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.