Home » News & Articles » Specialty Metals for Space Exploration

WATCH THE PRESENTATION BELOW

Backed by a knowledgeable on-site team and robust local delivery options, we can meet urgent material demands and keep production moving. Customers can also count on the same reliability and technical expertise they’ve come to expect from us—now with the added advantage of regional support.

Additionally, it’s easier than ever to get instant pricing, place orders, and track your shipments on your schedule at rolledalloys.com.

PRESENTATION SLIDES

Specialty Metals for Space Exploration

Welcome, readers, to a deep dive into the fascinating world of specialty metals for space exploration, inspired by a recent Rolled Alloys webinar. Hosted by Nick Hicks, an applications engineer at Rolled Alloys, the session offered a comprehensive look at the metals that are revolutionizing space technology. From the most commonly utilized materials like austenitic stainless steels to the complexities of super alloys, we’ll explore how these metals are pushing the boundaries of what’s possible in the harshest environments known to man.

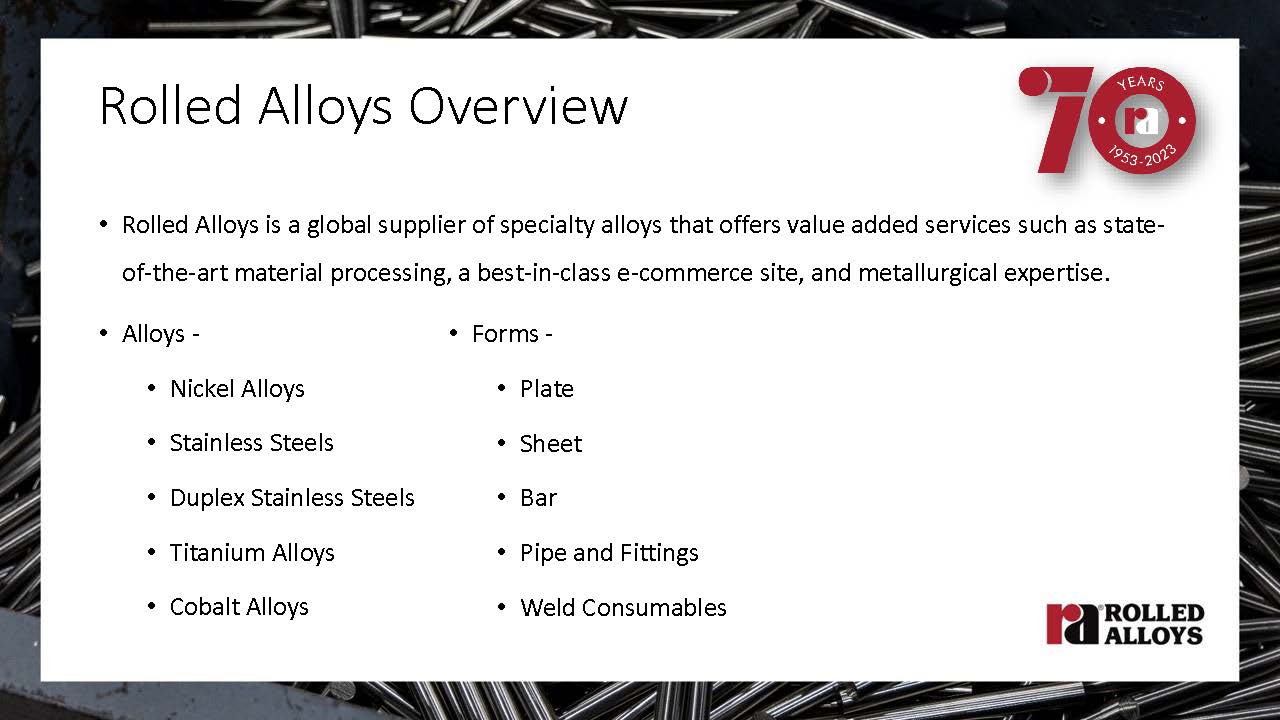

A Brief Overview of Rolled Alloys

Rolled Alloys is a global supplier of specialty alloys that offers a range of value-added services, including state-of-the-art material processing and metallurgical expertise. The company deals in various alloys such as nickel, stainless steels, duplex specialty stainless steels, titanium alloys, and cobalt alloys, catering to diverse forms like plates, sheets, bars, pipes, and fittings.

Commonly Utilized Materials in Space Exploration

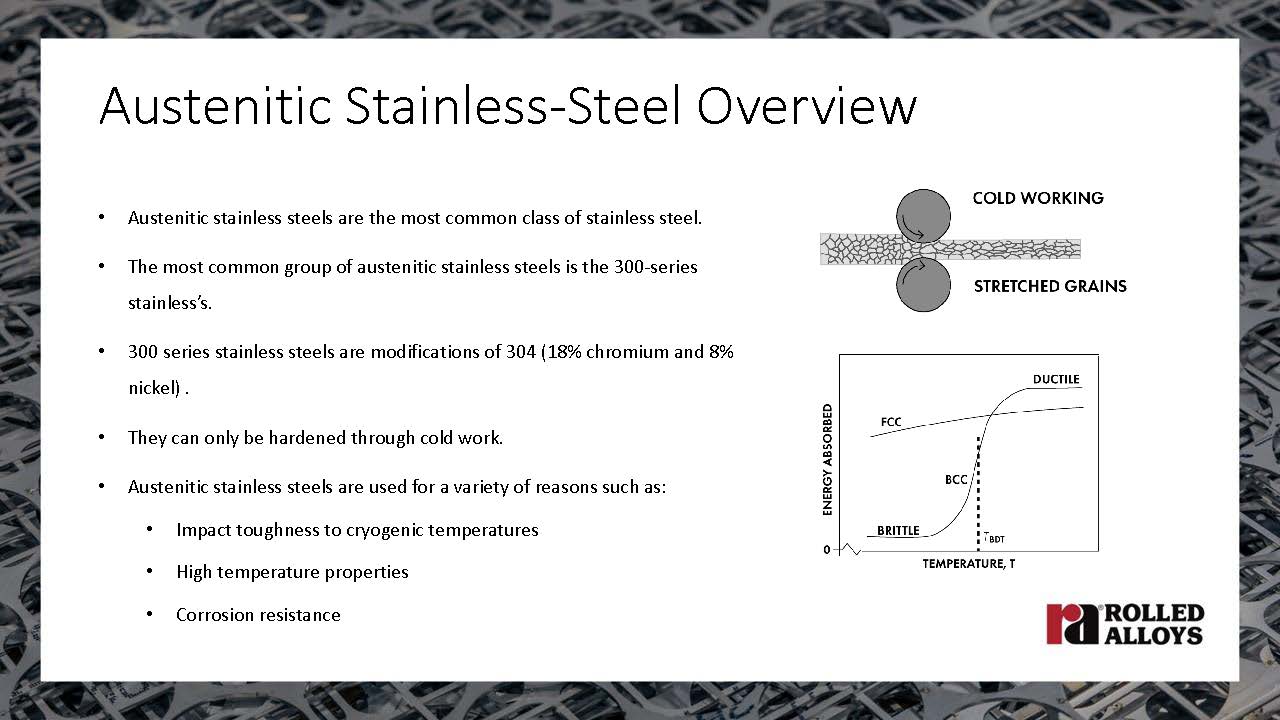

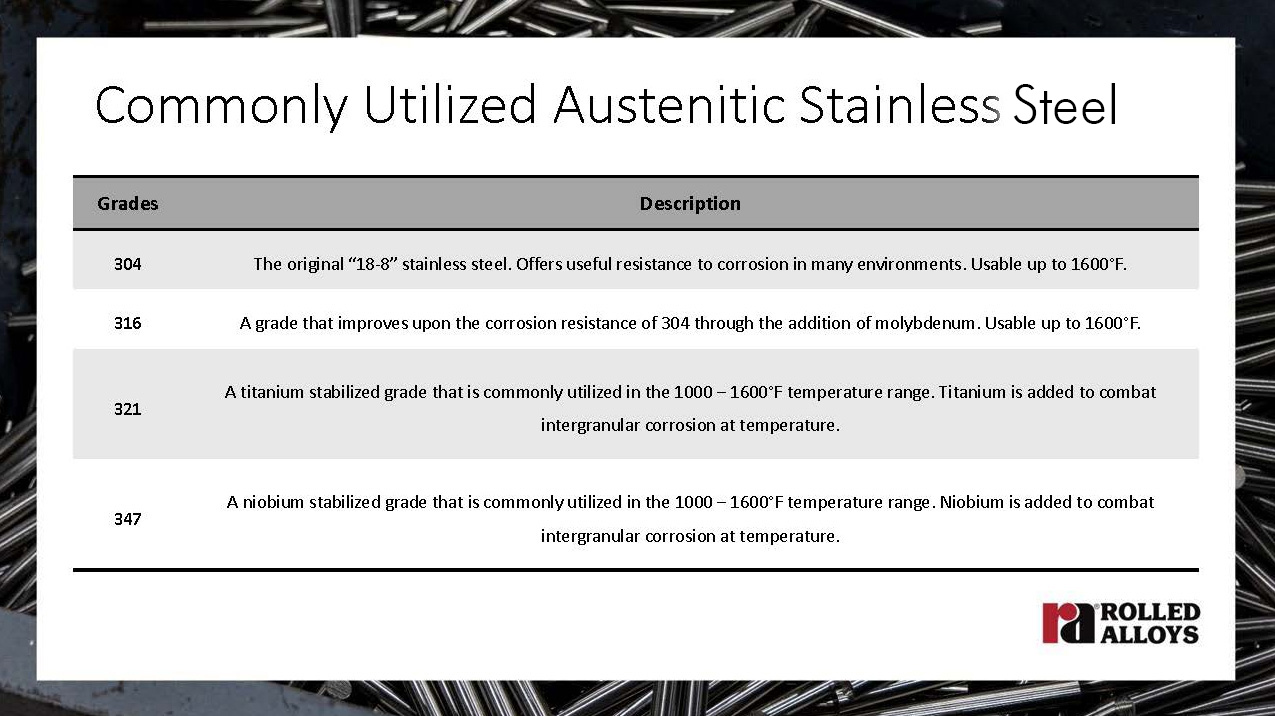

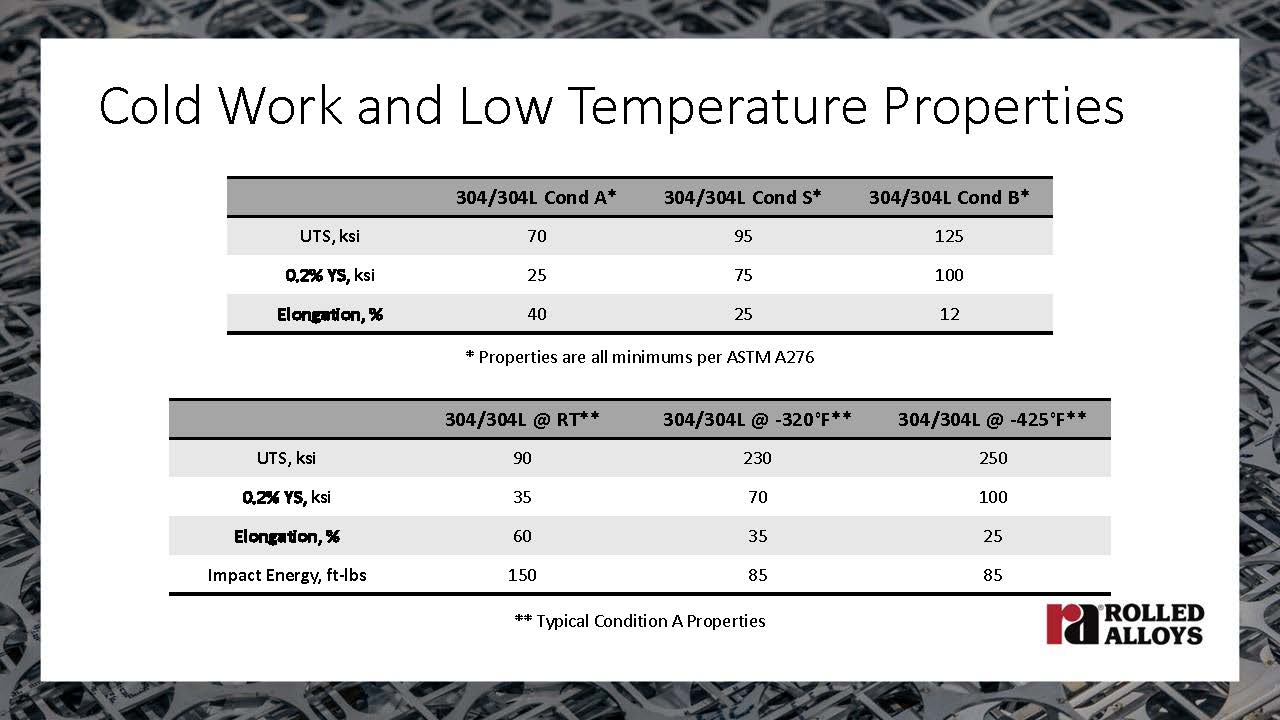

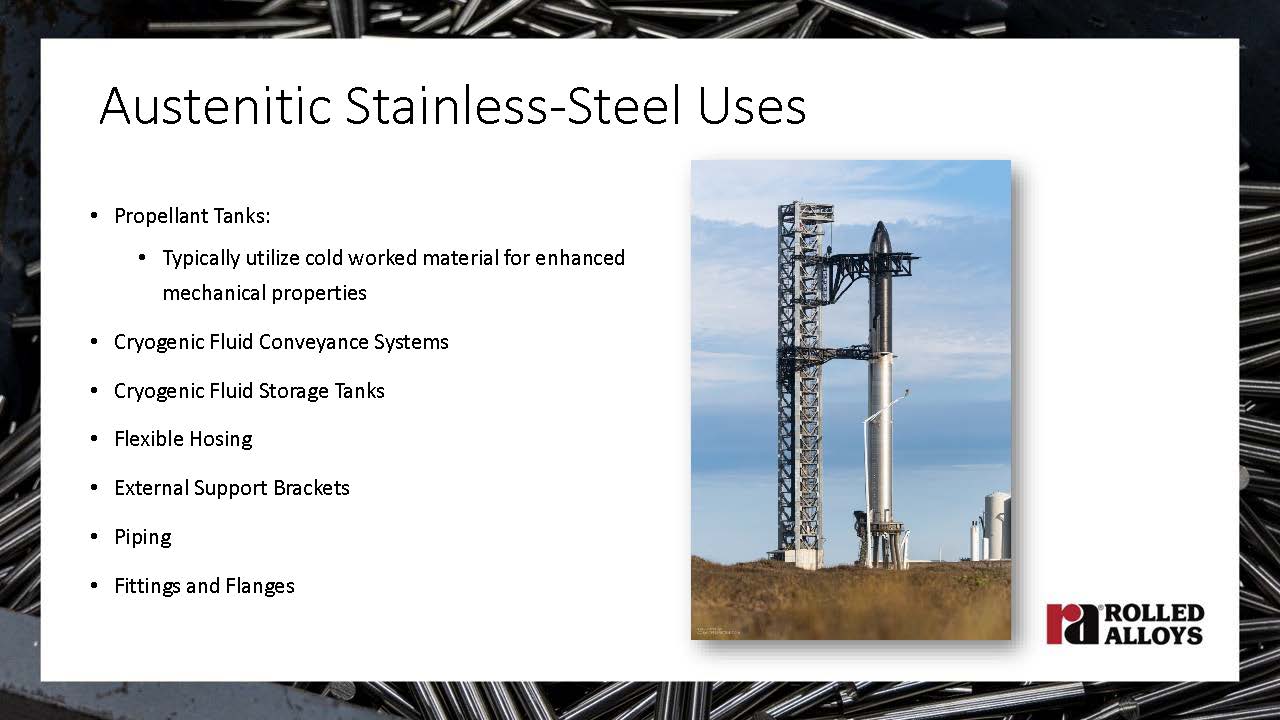

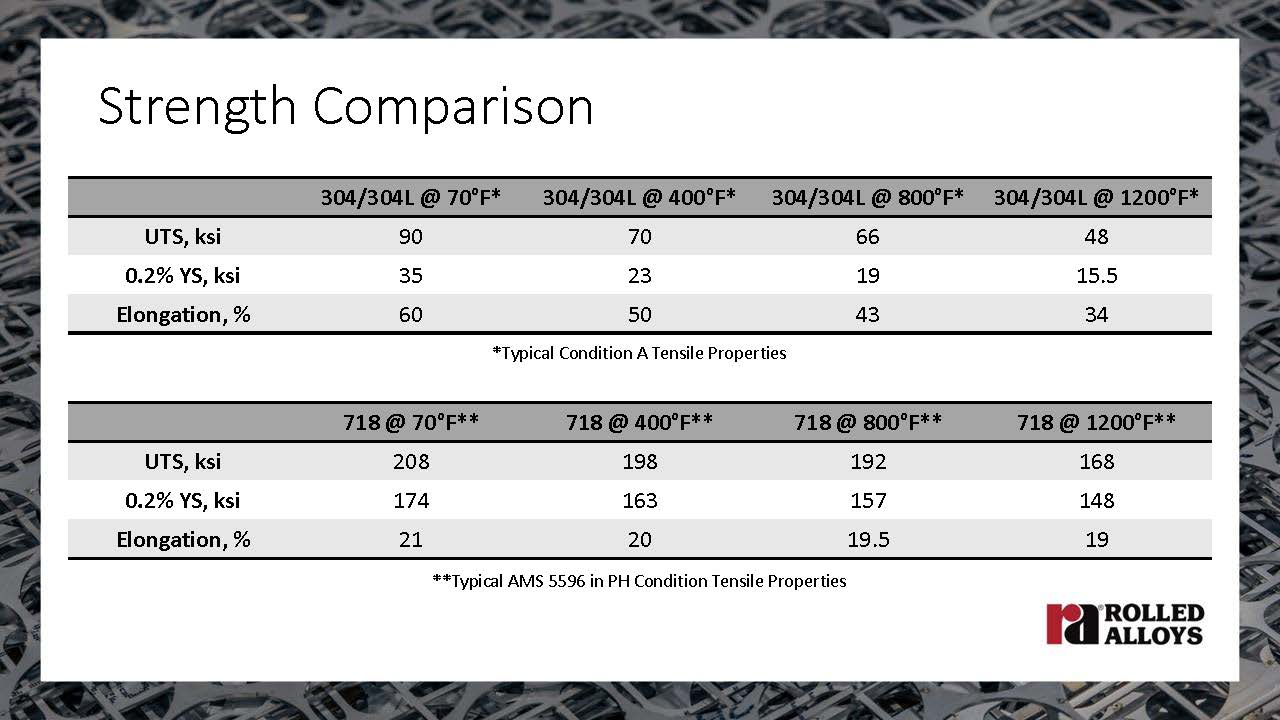

- Austenitic Stainless Steels: Austenitic stainless steels, particularly the 300 series, are the most commonly used class of stainless steel in space exploration. Among them, 304 and 316 are frequently employed due to their excellent corrosion resistance and usability at high temperatures (up to 1600°F). These materials also perform well at cryogenic temperatures, maintaining impact toughness without undergoing a ductile-to-brittle transition, making them ideal for cryogenic conveyance systems, propellant tanks, and other critical components in space applications.

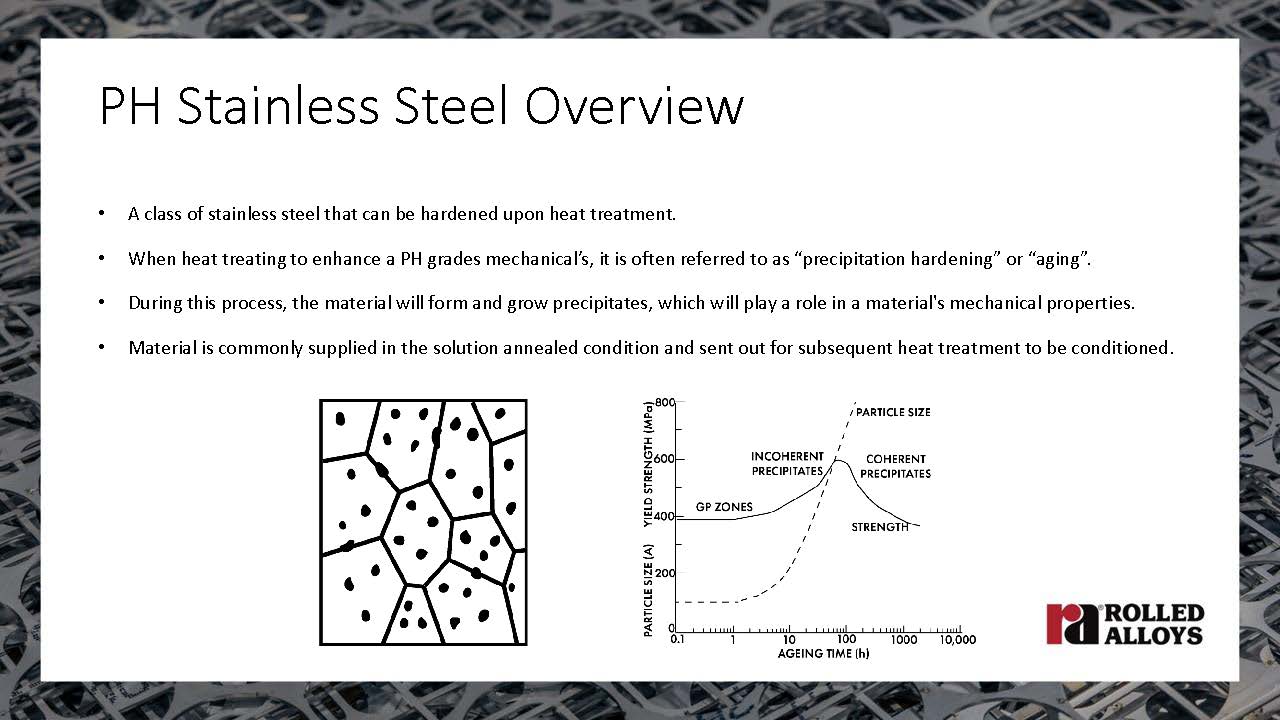

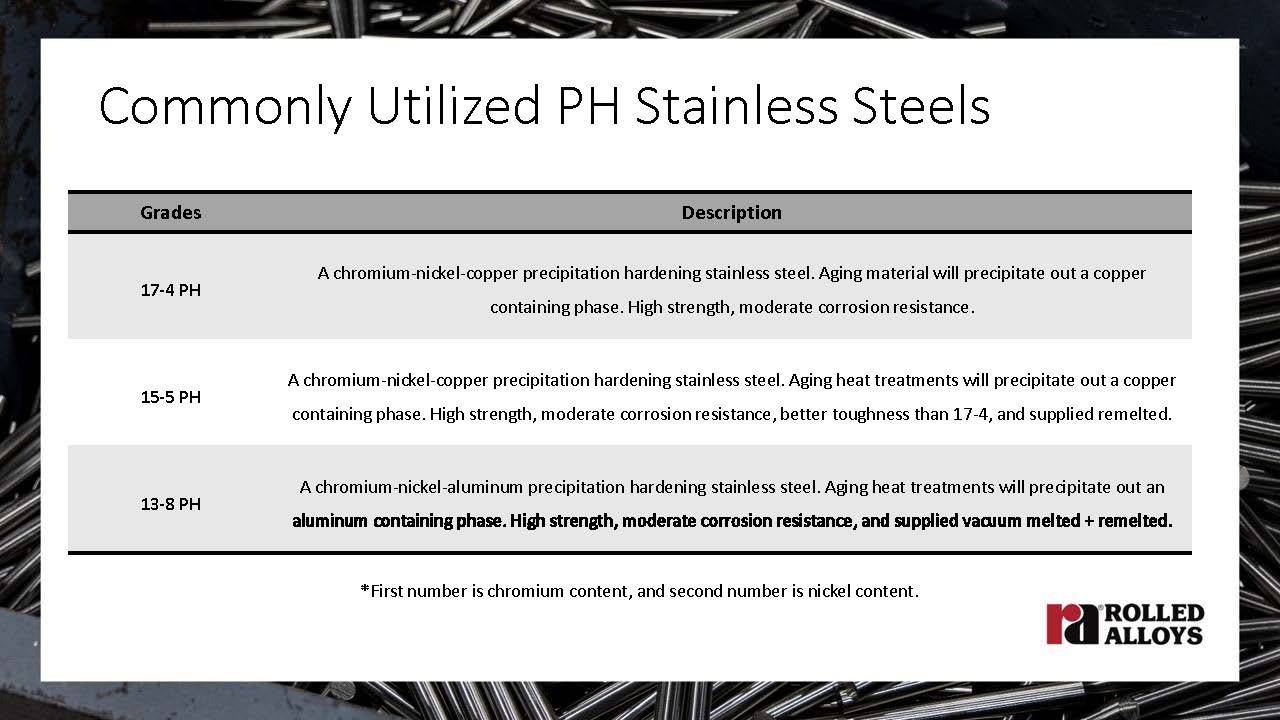

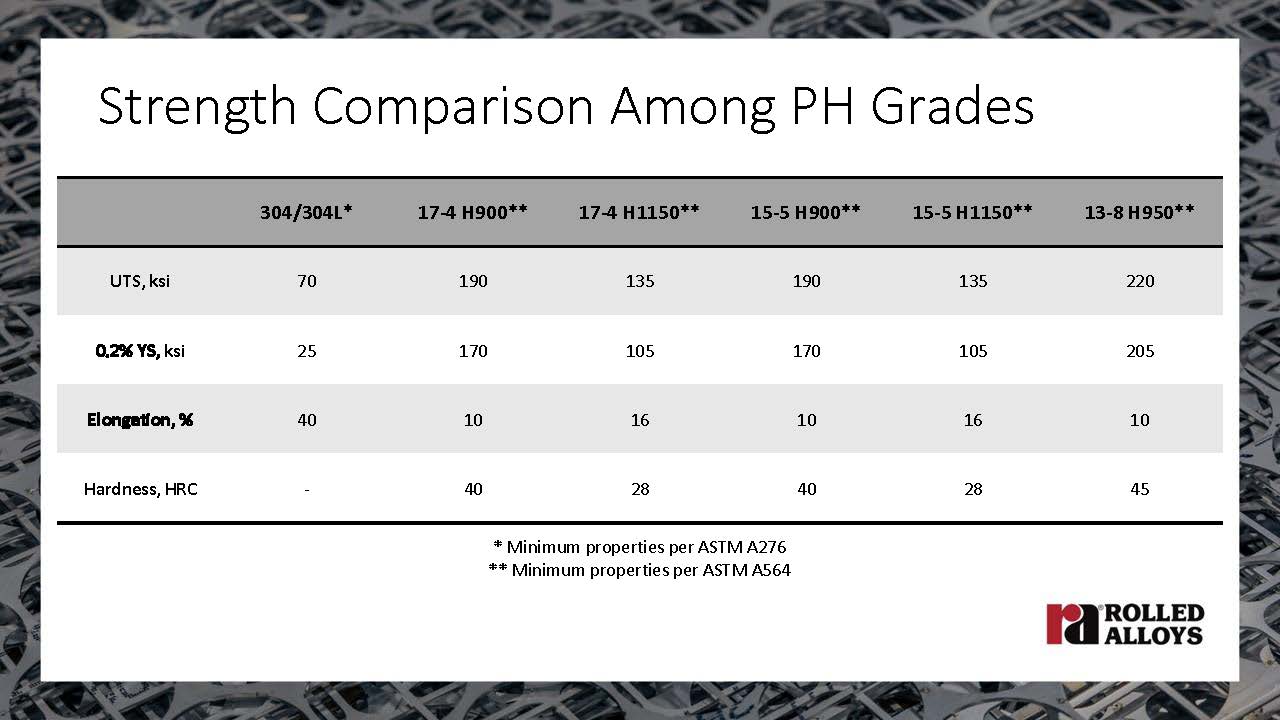

- Precipitation-Hardened (PH) Stainless Steels: PH stainless steels like 17-4, 15-5, and 13-8 offer the advantage of being hardenable through heat treatment, enhancing their mechanical properties. These materials are essential in applications requiring high strength but moderate corrosion resistance, such as fasteners, bearings, and high-wear surfaces. The aging process in these steels allows for precise control over mechanical properties, making them versatile in demanding aerospace applications.

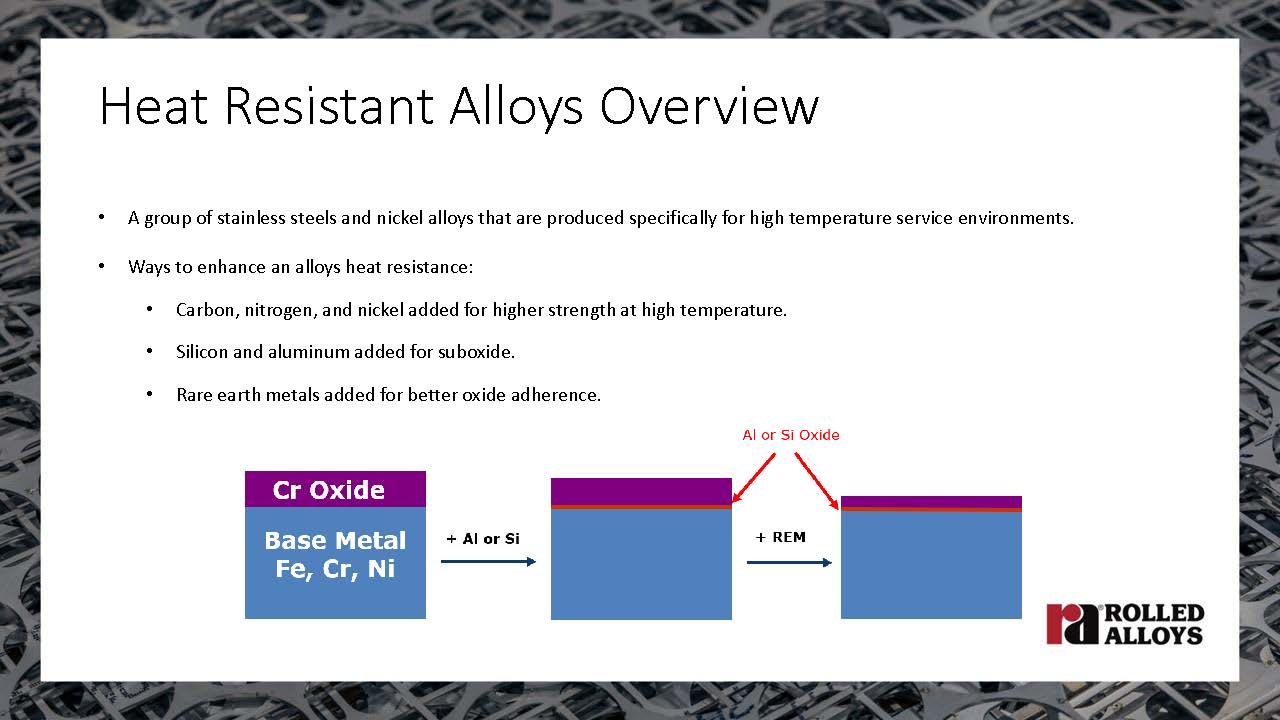

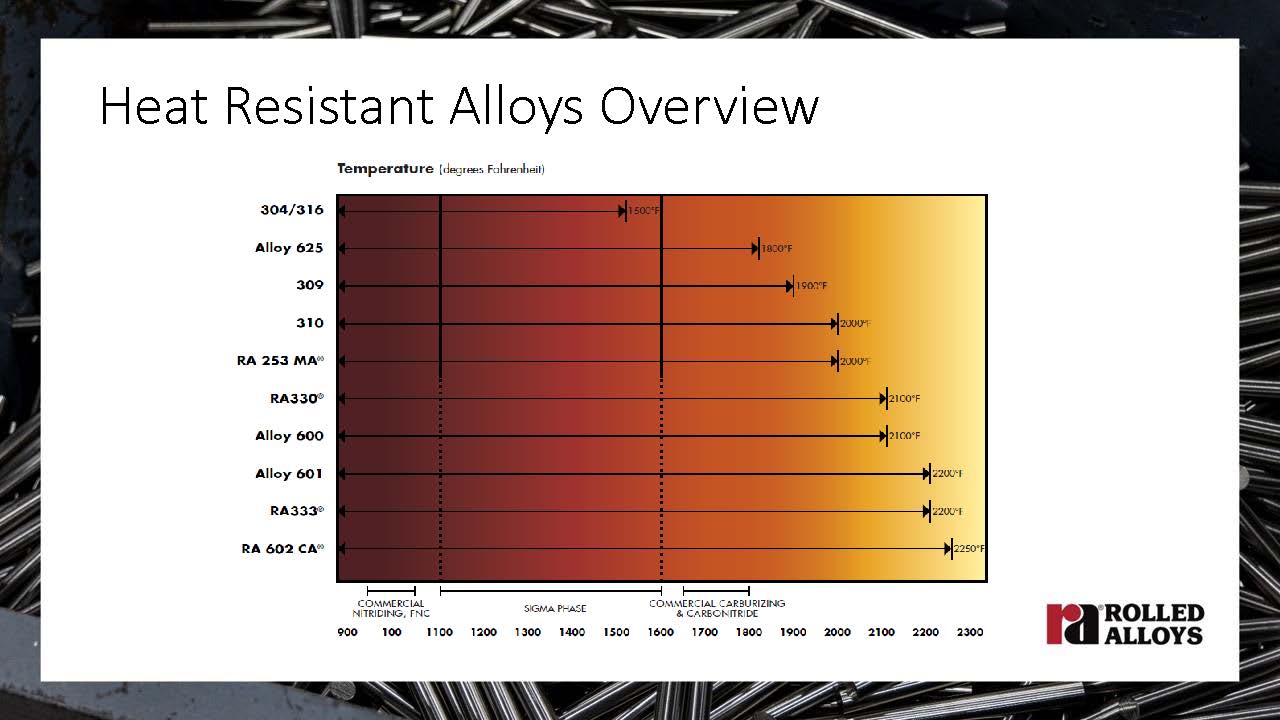

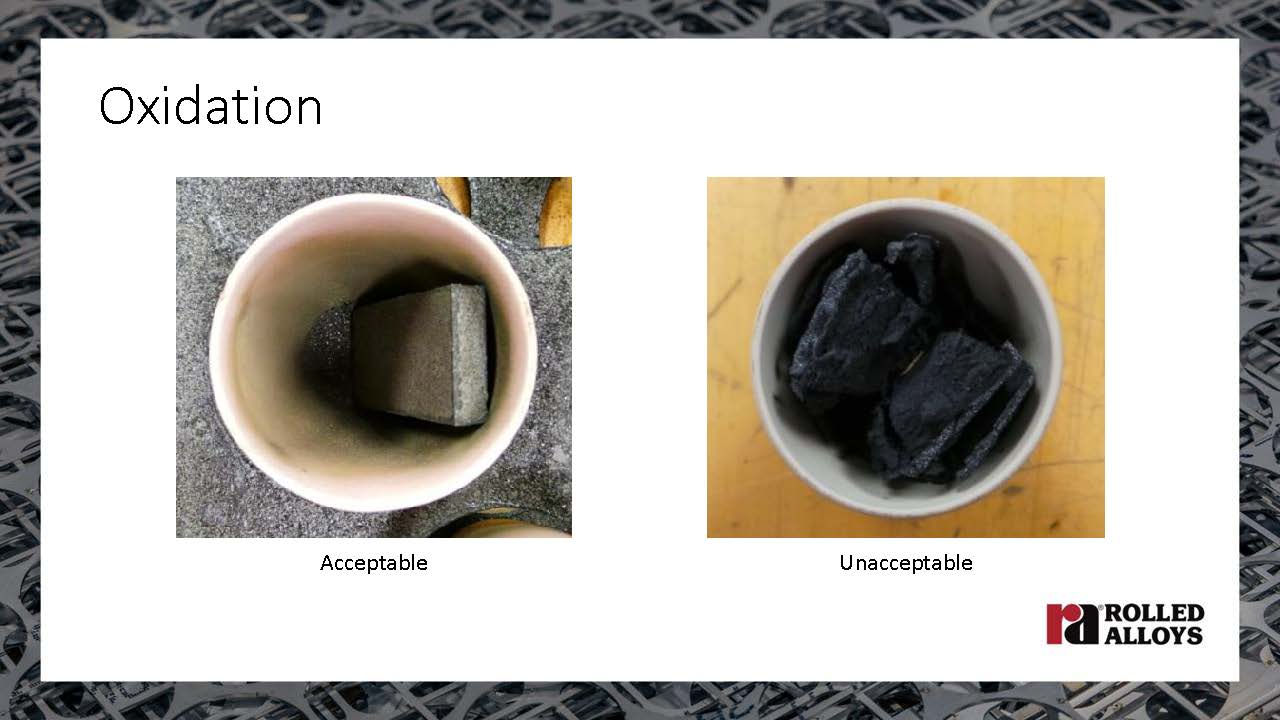

- Heat Resistant Alloys: Heat-resistant alloys, including certain stainless steels and nickel alloys, are designed for high-temperature service environments. By incorporating elements like silicon, aluminum, and rare earth metals, these alloys form protective oxide layers that enhance their resistance to oxidation and corrosion at elevated temperatures. Heat-resistant alloys are critical in components exposed to extreme temperatures, such as engine internals, metallic heat shields, and high-temperature structural elements in spacecraft.

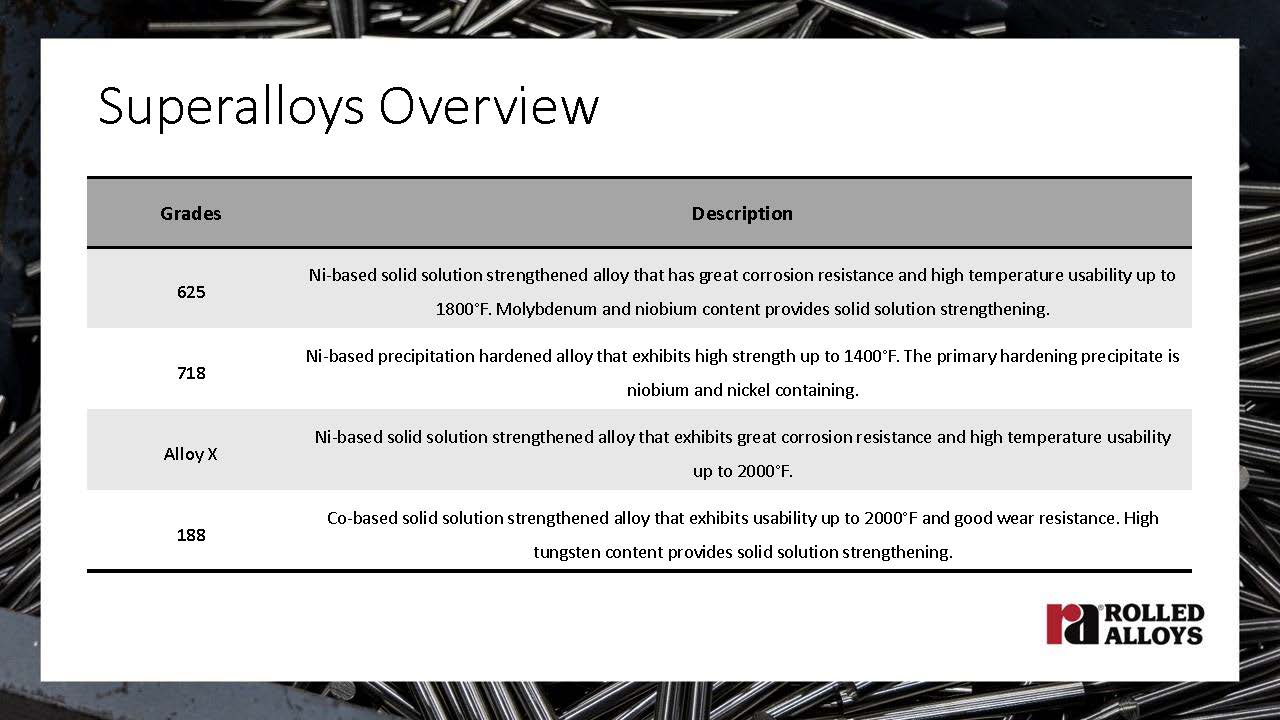

- Super Alloys: Super alloys, which include nickel-based, cobalt-based, and iron-based alloys, are the pinnacle of high-performance materials in space exploration. These alloys exhibit exceptional strength, corrosion resistance, and stability at high temperatures. Notable examples like Inconel 625, Inconel 718, and alloy X are used in high-stress, high-temperature environments, including rocket engines, turbopumps, and heat shields. Their ability to maintain mechanical properties under extreme conditions makes them indispensable in the aerospace industry.

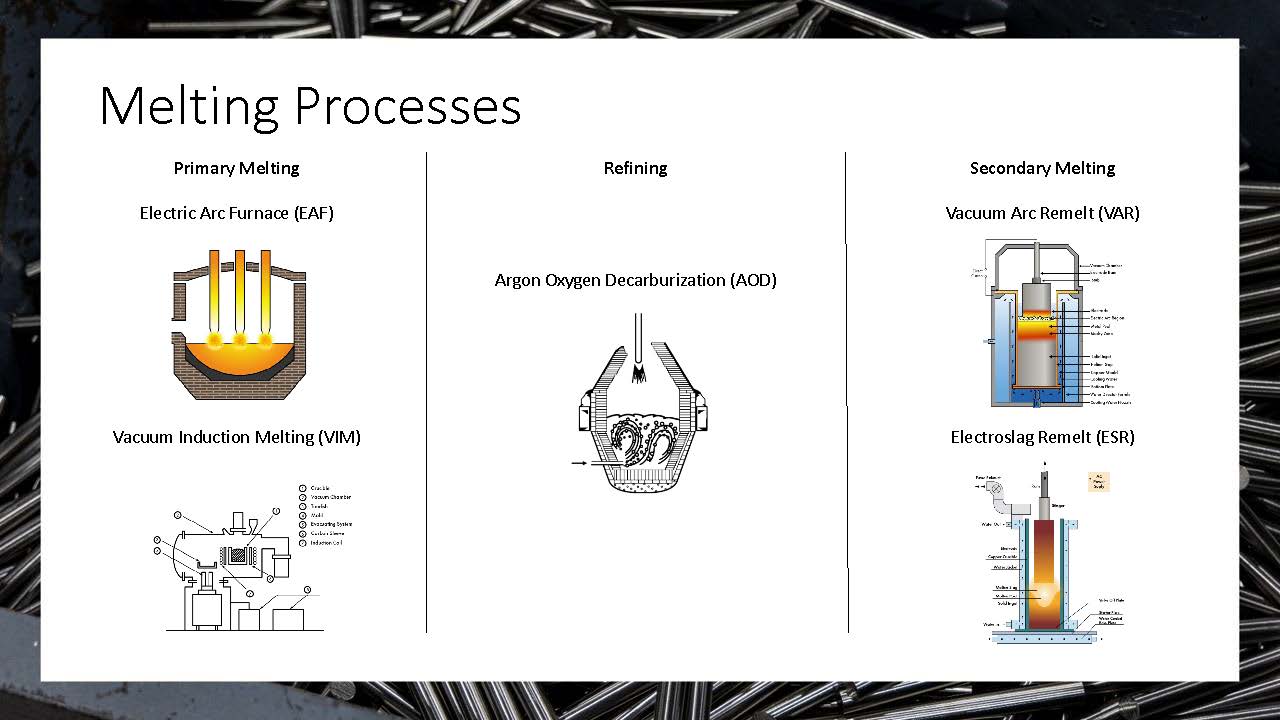

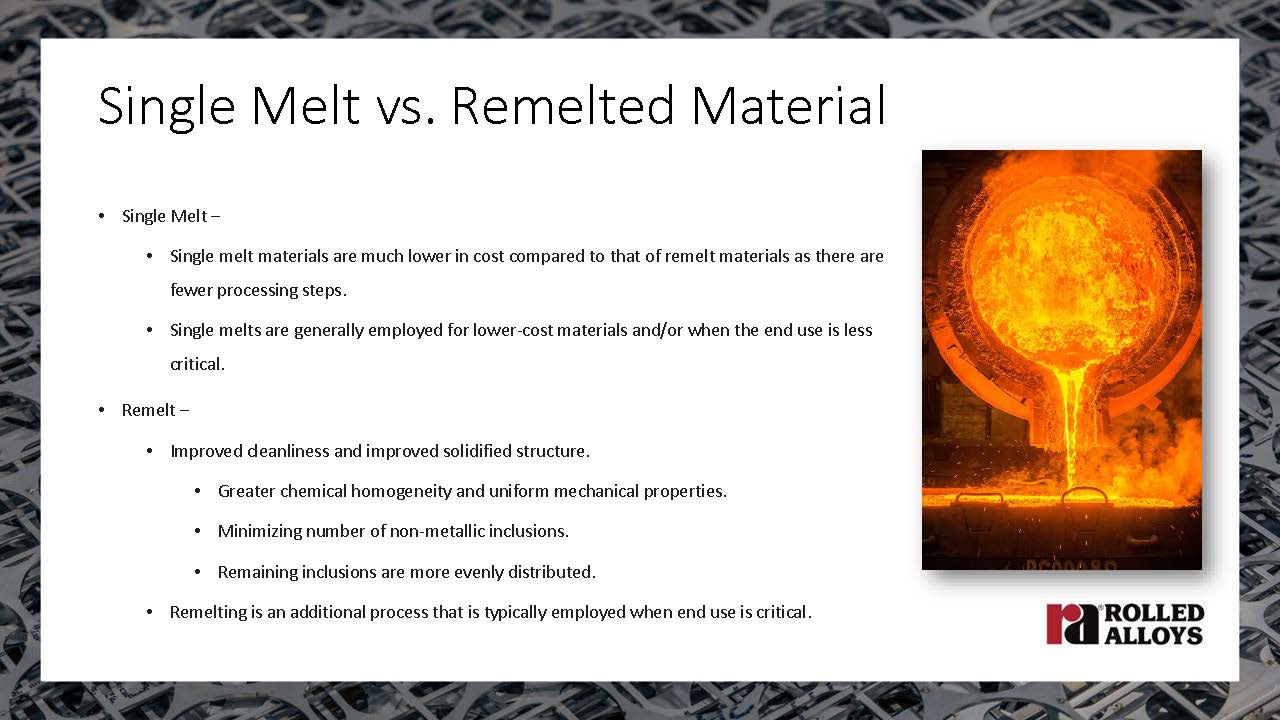

The Importance of Melting Practices

Melting practices play a crucial role in determining the quality and performance of specialty metals. The process typically involves primary melting, refining, and, in some cases, secondary melting or remelting processes. Each step is critical in achieving the desired microstructure and properties, ensuring that the material can withstand the rigorous demands of space exploration.

Conclusion

Specialty metals are at the heart of space exploration, enabling the creation of components that can endure the extreme conditions of space. The insights shared by Nick Hicks during the Rolled Alloys webinar underscore the importance of selecting the right materials and processes to ensure the success of aerospace missions. By leveraging advanced metallurgical practices and a deep understanding of material behavior, manufacturers can push the boundaries of what’s possible in the final frontier.

For more information or to explore how Rolled Alloys can support your space exploration needs, contact the Rolled Alloys Metallurgical Services group at 1-800-521-0332 or submit your questions below.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.