New Stainless Products 420 & 17-4 Flat Bar

New Stainless Steel Products 420 | 17-4 Flat Bar 420 Stainless Steel Bar We’ve recently announced the addition of 420 Stainless Round Bar to its inventory. 420 is a 12% chromium, martensitic stainless steel. 420 provides improved hardenability and strength compared to 410 stainless. 420 stainless bar inventory meets DFARs sourcing requirements. “With the addition […]

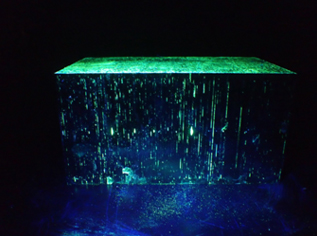

Inclusions in Specialty Alloys

When molten metal (steel, stainless steel, or nickel alloys) solidifies, the center of an ingot or slab is the last to freeze. While non-metallic impurities (oxides, nitrides, sulfides, silicides) settle throughout the ingot or slab, the greatest concentration of these inclusions settle along the solidification front…

How to Weld Duplex Stainless Steel

How to Weld Duplex Stainless Steel basic rules and guidelines to help minimize issues Rolled Alloys Metallurgical Services often receive questions about welding duplex stainless steel and general rules to follow to maintain corrosion resistance and properly preserve mechanical properties. This article will discuss basic rules and guidelines to help minimize potential issues that may […]

What is Sensitization and How to Avoid It?

What is Sensitization and How to Avoid It? Sensitization is a phenomenon that can occur in stainless steel and even some nickel alloys. It is a critical concept that needs to be understood as it can adversely affect the performance of stainless steel and nickel alloys. Sensitization is the precipitation of carbides at grain boundaries […]

How Stainless Steel Rusts

How Stainless Steel Rusts All grades of stainless steel contain a minimum of 10.5% chromium within their chemical composition which allows for them to form a continuous protective oxide layer along their surface. This oxide layer is what makes stainless steel resistant to rusting and other forms of corrosion. Although stainless steel has this protective […]

Stop Corrosion Before It Starts

Stop Corrosion Before It Starts Corrosion can occur when an alloy is exposed to moisture and other elements or chemicals which cause the material to deteriorate. Rolled Alloys has put together a list of tips to help you avoid corrosion. Choose Stainless Steel: Although all metals can corrode, stainless steels are more resistant to corrosion […]