Processing Tolerances

Tolerances are the maximum and minimum limits of a dimension, or other physical trait, that are acceptable for a product to function properly. They are often used in engineering drawings and manufacturing to control parts and imperfections that may arise from manufacturing errors, improper tool usage, or other issues.

AL-6XN® Case Study

Coal-fired power plants generate flue gas as a byproduct of combustion. In many modern plants, especially those burning coal with high sulfur and chloride content, this flue gas can become highly corrosive to carbon steel and even conventional stainless steels.

RA 253 MA® vs 309/310

The main difference between RA 253 MA and both 309 and 310 stainless steel lies in alloy composition and resulting high‑temperature performance. RA 253 MA contains micro‑alloy additions of cerium, silicon, and nitrogen, which enhance oxidation resistance and creep strength at elevated temperatures. In addition, RA 253 MA has a lower overall nickel and chromium content, making it less susceptible to fluctuations in commodity pricing when compared to 309 and 310 stainless steels.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

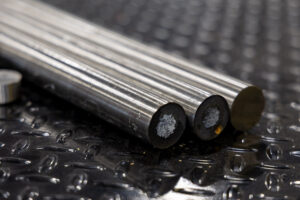

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.

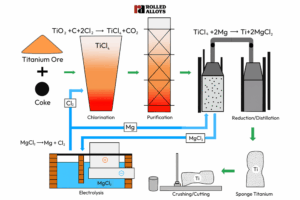

How the Kroll Process Produces Titanium Sponge

The Kroll process is the primary industrial method for transforming titanium ore into metallic titanium…