Home » News & Articles » Welding Consumable Designations and Selection Criteria

Welding Consumable Names and why they Matter

Welding consumables play a crucial role in welding, and understanding their naming conventions can significantly enhance the outcome of a weld. There are various ways that welding consumables are named, whether it be their chemical composition, mechanical strength, coating, or specific group. This system provides essential information and helps engineers and welders select appropriate consumables. Whether you are looking for a shielded metal arc welding (SMAW) electrode or a tungsten inert gas (TIG) welding rod, comprehending the meaning behind different designations is essential.

This article will discuss the designations of stainless steel and nickel alloy welding consumables and outline important factors to consider when selecting a consumable for your needs. For instance, choosing the right electrode involves understanding the base metals, the welding position, the application environment, and desired properties. By considering these factors, you can ensure you achieve the best possible weld while meeting the specific requirements of your project.

Weld Designation Standards

The American Welding Society (AWS) has several standards for stainless steel and nickel alloy welding consumables, including AWS A5.4, AWS A5.9, AWS A5.11, and AWS A5.14. These specifications define parameters such as chemical requirements, corresponding UNS numbers, typical weld metal tensile strengths, and intended use descriptions of specific welding consumables. For example, the designations ER309 and ERNiCr-3 help identify the composition and use of the electrodes.

- The prefix “E” indicates the wire can be used as an electrode.

- The “R” indicates the wire is a bare filler rod.

For stainless steel designations like ER309, the number following the letters refers to the steel type. ER309 is the matching filler metal for 309 stainless steel and can function as an electrode or rod. For nickel alloys like ERNiCr-3, the letters following ER indicate the primary chemical elements—Nickel (Ni) and Chromium (Cr)—with nickel being the major component.

SMAW electrodes differ slightly. For example, in the designation E304L-15:

- The absence of “R” shows that this consumable is not a bare rod.

- SMAW electrodes have flux coatings, which are critical in shielding the weld.

- The number following the dash (e.g., -15) identifies the type of flux coating.

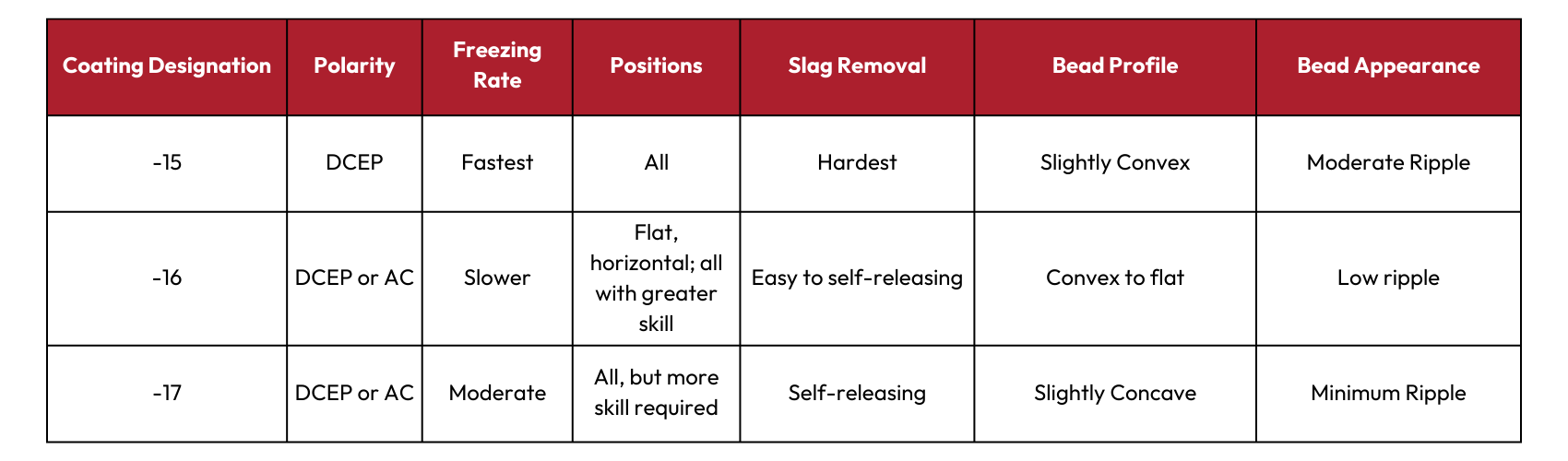

Rolled Alloys has designed and stocks welding consumables for its proprietary materials, and they follow a similar format to other designations. For example, RA330-04 relates to RA330, with the -04 demonstrating a difference in chemistry from the base material. For coated electrodes, RA330-04 can be followed by either a -15 or a -16, which defines what flux the electrode is coated in. Below is a table that provides information on standard stainless steel and nickel alloy SMAW electrode coatings and their welding characteristics.

Types of Welding Polarity

Polarity is an important consideration in welding. The three primary polarities used are:

- Direct Current Electrode Positive (DCEP): Also known as reverse polarity, where the electrode is connected to the positive terminal.

- Direct Current Electrode Negative (DCEN): Also known as straight polarity, where the electrode is connected to the negative terminal.

- Alternating Current (AC): The current changes direction several times per second, causing the arc to extinguish and re-strike rapidly.

Understanding what polarities your welding machine supports and what is recommended for the welding consumable ensures optimal welding conditions.

Factors to Consider in Selecting a Weld Consumable

Selecting the correct weld consumable is critical for weld strength, durability, and corrosion resistance. If an incorrect welding consumable is selected, welds can be a significant area of weakness. Key considerations in choosing a weld consumable include:

- Base Materials: Matching filler metals are usually preferred when welding similar materials. These are often over-alloyed for additional strength (e.g., RA330-04 contains more carbon and manganese than RA330). When welding dissimilar materials, a consumable that meets or exceeds the strength and/or corrosion resistance of the better of the two base materials should be selected. In addition, dissimilar welding can often lead to microstructural considerations, especially in the case of stainless steel.

- Environmental Conditions: Choose a weld consumable that will withstand the final application’s environment, whether corrosive, high-temperature, or a combination of the two.

- Welding Location: Whether welding is done in a shop or the field, the location must be considered, as it can limit the welding process and consumables used.

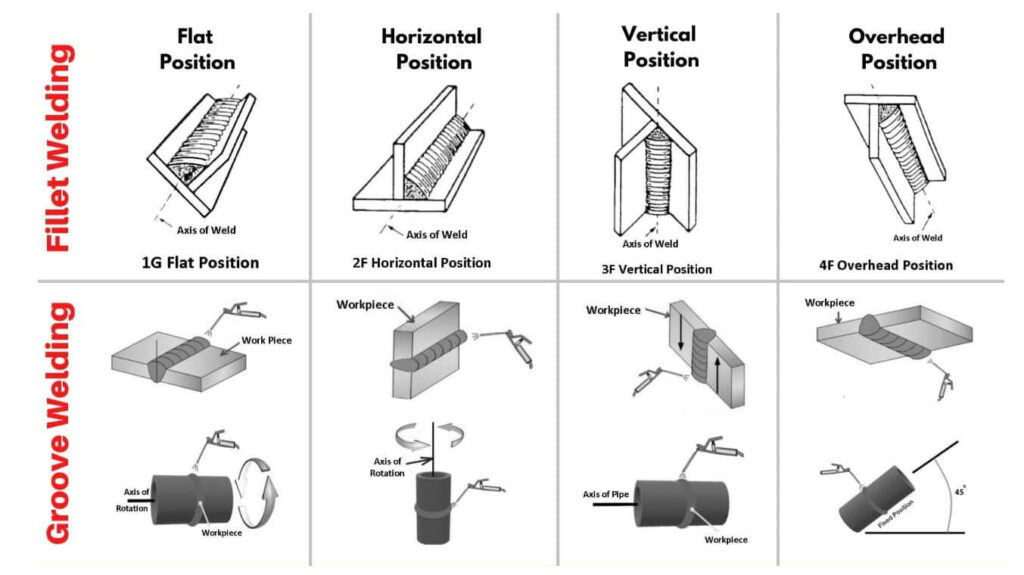

- Welding Position: Certain processes and consumables are limited by welding position. Planning based on vertical, overhead, flat, or horizontal welding positions is essential. The four primary welding positions are shown below, increasing difficulty from left to right.

Conclusion

Anyone involved in the welding process must understand welding consumables and their designations. These designations convey critical information about composition and use. By considering welding parameters, base materials, and environmental conditions, engineers and welders can make informed decisions, enhance process efficiency, improve safety, and ensure high-quality welds that meet industry standards.

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

AL-6XN Case Study

AL-6XN® Case Study AL-6XN® Resisted corrosive environments at indianapolis power and light for over 5 years Specifications UNS: N08367 ASTM: B 688, A

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.