Home » News & Articles » Pipe Sizes and Tolerances

Nominal Pipe Sizes (NPS)

Steel pipe sizes are based on historical dimensions called Nominal Pipe Sizes (NPS) which standardize the nominal outside diameter (OD).

Additionally, a series of standard wall thicknesses known as Schedules (SCH) was also developed years ago. The units for both NPS and SCH are dimensionless. A larger number indicates a larger OD size or a heavier wall thickness. A typical description might look like 4 NPS SCH 40. In this case, this description indicates a nominal OD of 4.500” (114.3 mm) and a nominal wall thickness of 0.237” (6.02 mm). Through 8 NPS, the nominal dimensions for carbon and stainless alloy pipes are the same. In larger sizes, there are differences in some nominal wall thicknesses.

Historically, the dimensions for smaller diameter pipes were such that the inside diameter (ID) of what are now known as SCH 40 thicknesses were very close to the OD size designator. In the example above, the nominal ID is 4.026” for 4 NPS. As it became possible to make lighter (and heavier) wall thicknesses, the schedule of sizes was expanded. The sizes are standardized in ANSI B36.10 for carbon pipe and in ANSI B36.19 for stainless and nickel alloys.

Pipe tolerances will depend on the alloy and the standard to which it was produced. The general requirement standard covering most stainless pipe is ASTM/ASME A/SA 999. The OD under tolerance on all sizes is -0.031″. The over tolerance increases with OD size, but for the range of 1-1/2 to 4 NPS, the plus tolerance is also 0.031″.

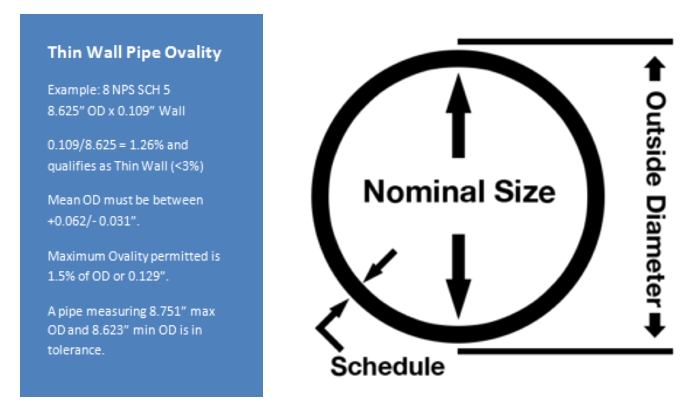

This introduces the concept of ovality, where if the pipe exhibited both the maximum and minimum OD permitted, it would be out of round (oval) by 0.062”. An additional ovality allowance is permitted for thin wall pipe, which is defined as a pipe where the nominal wall is 3% or less of the OD. In such a case, the OD tolerance range applies to the mean OD, and the ovality is permitted to be 1.5% of the OD. (See Inset).

Only the minimum wall thickness is limited, which is -12.5% of the nominal wall. There is no maximum wall thickness limit. For seamless pipe, there is a limit of 10% by weight (mass) over the nominal weight. Note that this limits the average wall thickness of the seamless pipe to be no more than 10% heavy but does not limit the specific maximum wall thickness at any given point. There is no maximum thickness or weight limit for welded pipe.

Tolerances are also provided for stainless pipe on straightness (1/8” in 10’) and cut lengths (-0, +1/4”). Notice that there is no requirement or tolerance for the ID. Most nickel alloy welded pipe tolerances are identical or very similar to those for stainless. The general requirements for nickel alloy welded pipe are contained in ASTM/ASME B/SB 775. General seamless nickel alloy pipe requirements are published in ASTM/ASME B/SB 829. Because nickel alloys are more difficult to hot work, tolerances for hot-finished pipe are more generous than for stainless steel or welded and cold-finished nickel alloy products.

A comprehensive pipe size chart can be found on our website by clicking the below link.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.