Home » News & Articles » Best Practices When Using Specialty Materials for SWRO Feed and Brine Reject Lines

Selecting materials for Saltwater Reverse Osmosis (SWRO) applications demands precision and expertise.

In this comprehensive guide, we delve into the evolution of material selection strategies, exploring corrosion-resistant alloys and their performance in SWRO environments.

WATCH THE PRESENTATION BELOW

PRESENTATION SLIDES

SUMMARY

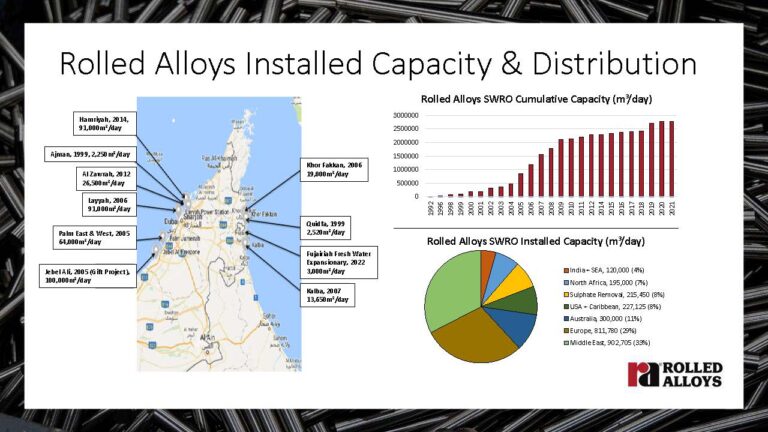

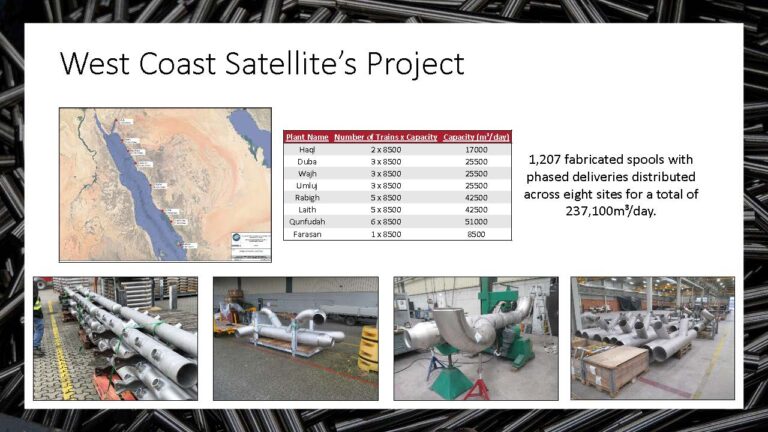

Understanding Material Selection for SWRO: The journey begins by understanding the pivotal role of specialty alloys in SWRO systems. Rolled Alloys, a global supplier, offers a range of state-of-the-art materials, including nickel alloys, stainless steels, titanium, and cobalt alloys. Their expertise lies in providing technical assistance, laboratory services, and innovative solutions for the industry.

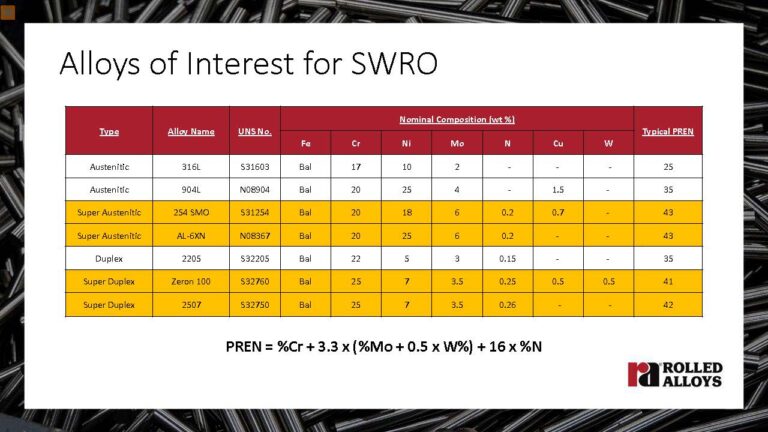

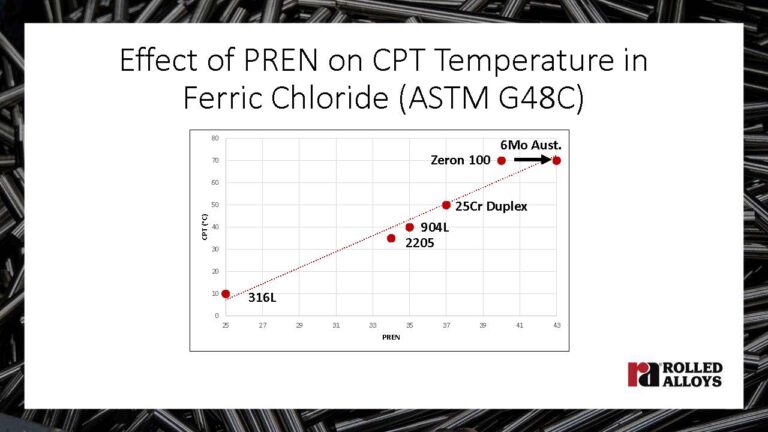

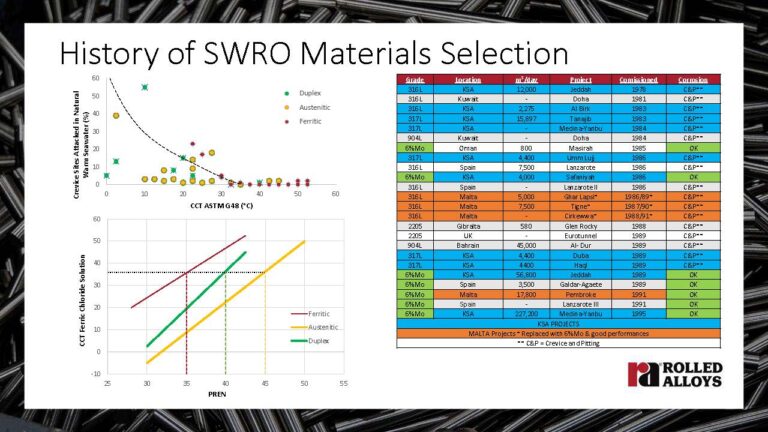

Corrosion Resistance in Stainless Steels: Dr. Byrne, an industry expert, outlines the correlation between compositions of stainless steels and their resistance to corrosion. Factors like Pitting Resistance Equivalent Number (PREN) play a crucial role in determining the seawater resistance of these alloys.

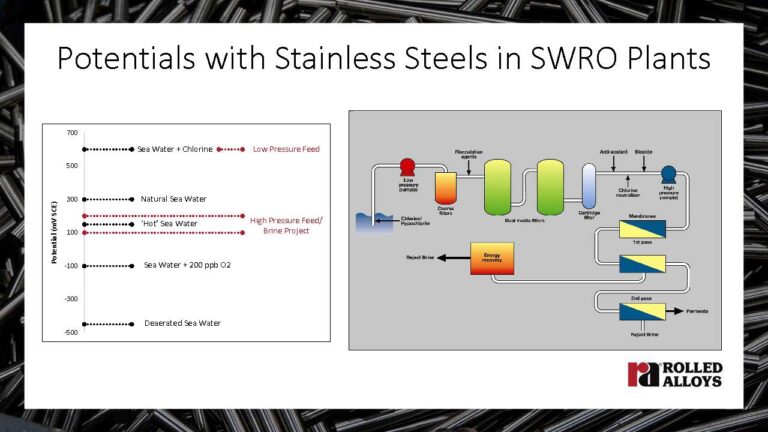

Historical Evolution and Challenges: The historical journey reveals the trial-and-error phase in material selection, highlighting challenges faced by using lower-grade stainless steels like 316. Instances of pitting and crevice corrosion led to the realization that higher-grade materials, like 6% molybdenum alloys and super duplex stainless steels, were better suited for SWRO applications.

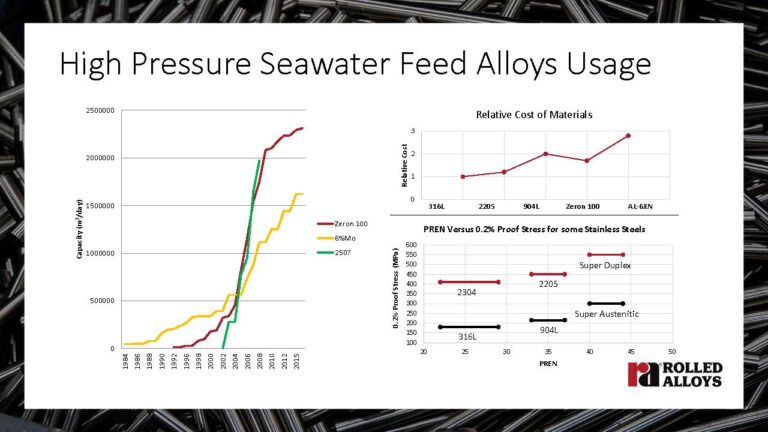

Transition to Advanced Grades: The late ’90s witnessed a transition towards advanced alloys, particularly super duplex stainless steels, as the industry embraced RO technology for larger municipal SWRO projects. This transition marked a significant shift from earlier materials due to their cost-effectiveness and superior performance.

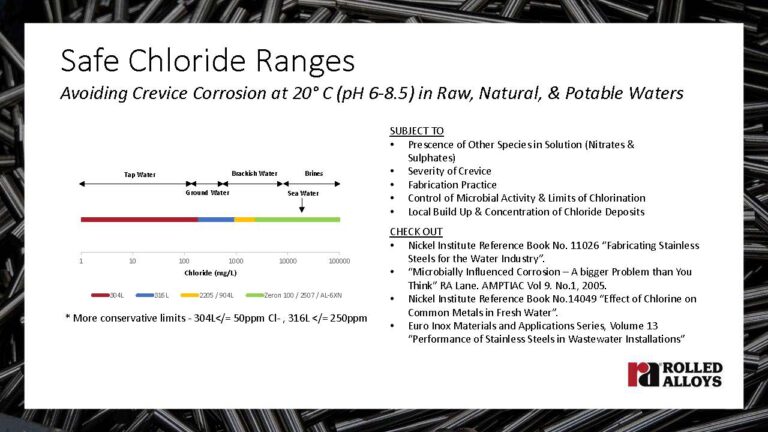

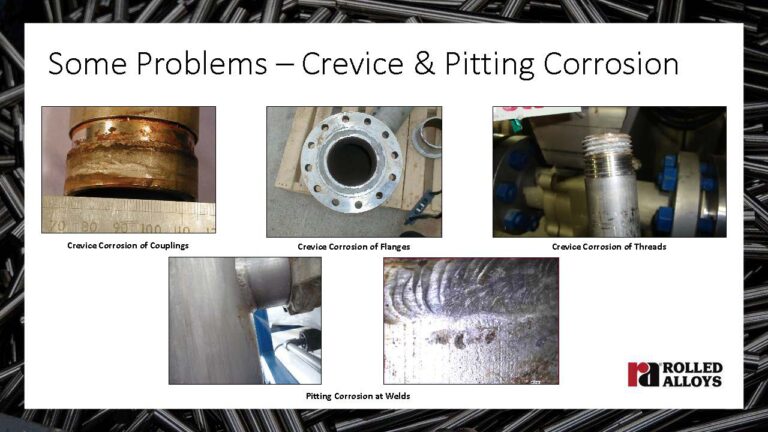

Challenges and Solutions in Material Selection: While 6% molybdenum alloys and super duplex stainless steels performed well, they weren’t immune to corrosion. Challenges such as crevice corrosion at connections and pitting corrosion of welds necessitated stringent adherence to best practices in manufacturing, fabrication, and treatment processes to minimize risks effectively.

Conclusion: Rolled Alloys stands as an industry leader, offering specialized expertise and a robust supply chain for SWRO projects. Their commitment to delivering quality materials and technical support underscores their position as a reliable partner in this niche market.

Key Takeaways:

- Evolution of material selection in SWRO from trial-and-error to advanced alloys

- Importance of corrosion-resistant alloys like super duplex stainless steels

- Challenges and cost-effectiveness in material selection for SWRO

- Rolled Alloys’ expertise and commitment to providing quality materials for SWRO projects

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

AL-6XN Case Study

AL-6XN® Case Study AL-6XN® Resisted corrosive environments at indianapolis power and light for over 5 years Specifications UNS: N08367 ASTM: B 688, A

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.