Home » News & Articles » How Stainless Steel Rusts

All grades of stainless steel contain a minimum of 10.5% chromium within their chemical composition which allows for them to form a continuous protective oxide layer along their surface.

This oxide layer is what makes stainless steel resistant to rusting and other forms of corrosion. Although stainless steel has this protective layer, there are some circumstances where stainless steel can be susceptible to rusting.

These circumstances include:

1. Mechanical Damage

2. Contamination

3. Exposure to a corrosive atmosphere

4. Sensitization.

Mechanical damage is most typically characterized as scratches and/or gouges present on a materials surface and is usually the result of improper/rough handling or transport. In such instances, the protective oxide is broken, allowing oxygen to diffuse into the metal. Over time, this break in the oxide will reform in air, but this process is not instantaneous. If this oxide layer does not have sufficient time to reform and the area were to come in contact with a foreign substance (water, grease, detergents, acid, base, etc.), the internal material could oxidize before the protective layer reforms and could begin to rust. During shipping, the contact and rubbing of stainless steel against carbon steel is often sufficient to break the oxide, allowing rust to form on the stainless steel surface.

Contamination of stainless steel can occur when processing carbon steel alongside stainless steel. The problem with doing this is if residual iron particles from carbon steel were to embed themselves into the surface of a stainless steel, these particles would be much more susceptible to rusting and could act as an initiation site for rusting on the stainless steel surface. To avoid this, stainless steels and carbon steels should be processed on separate machinery with separate tools. Furthermore, stainless steels and carbon steels should not be stored alongside each other. It would be preferable to store them in different areas.

Subjecting a stainless steel to a corrosive agent (acids, bases, halogens, etc.) above the concentration and temperature of what it is capable of resisting can often result in something called general corrosion. General corrosion is a type of corrosion that takes place uniformly over the surface of a material, which in most cases, will take on the appearance of wide spread rust. In order to prevent this, one must select a material that can properly hold up to its respective process environment.

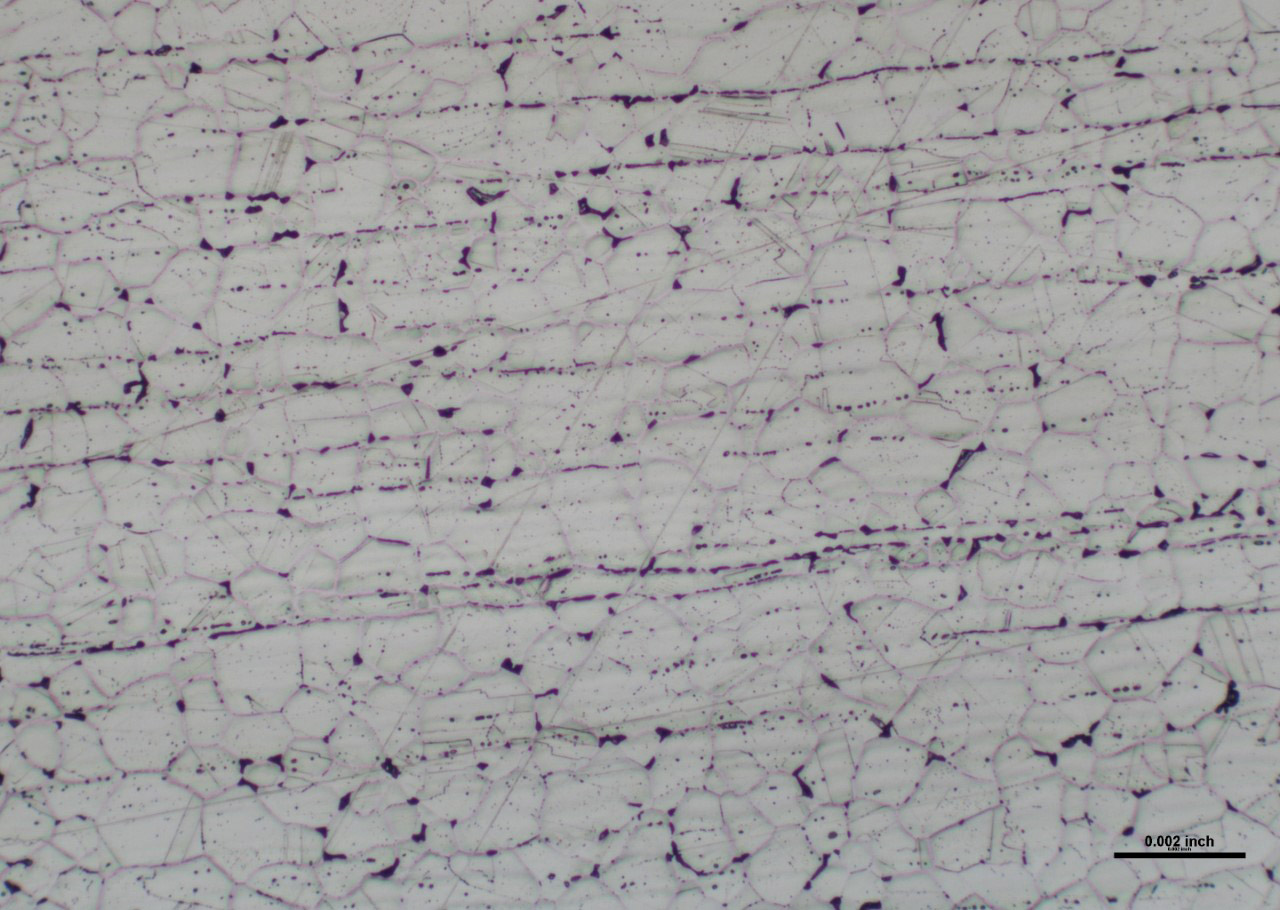

Finally, sensitization also is a condition that could result in stainless steel rusting. Sensitization is a form of intergranular corrosion that occurs in non-stabilized grades when subjected to temperatures in the range of 800°F – 1600°F for a time sufficient for carbides to precipitate in the grain boundaries. For this to occur, chromium diffuses from the grains to the carbon in the grain boundaries. Eventually, the chromium content adjacent to the grain boundary is reduced to less than 10.5%. At this point, the chromium is low enough that oxidation resistance is degraded, making these area much more prone to rusting. Once rust is formed, it often can move swiftly through other low chromium areas.

In summary, while stainless steels are resistant to rusting, they are not immune. In order to reduce the risk of rusting, it is important to consider these four factors.

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

AL-6XN Case Study

AL-6XN® Case Study AL-6XN® Resisted corrosive environments at indianapolis power and light for over 5 years Specifications UNS: N08367 ASTM: B 688, A

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.