Home » News & Articles » Process vs. Process

Process vs Process

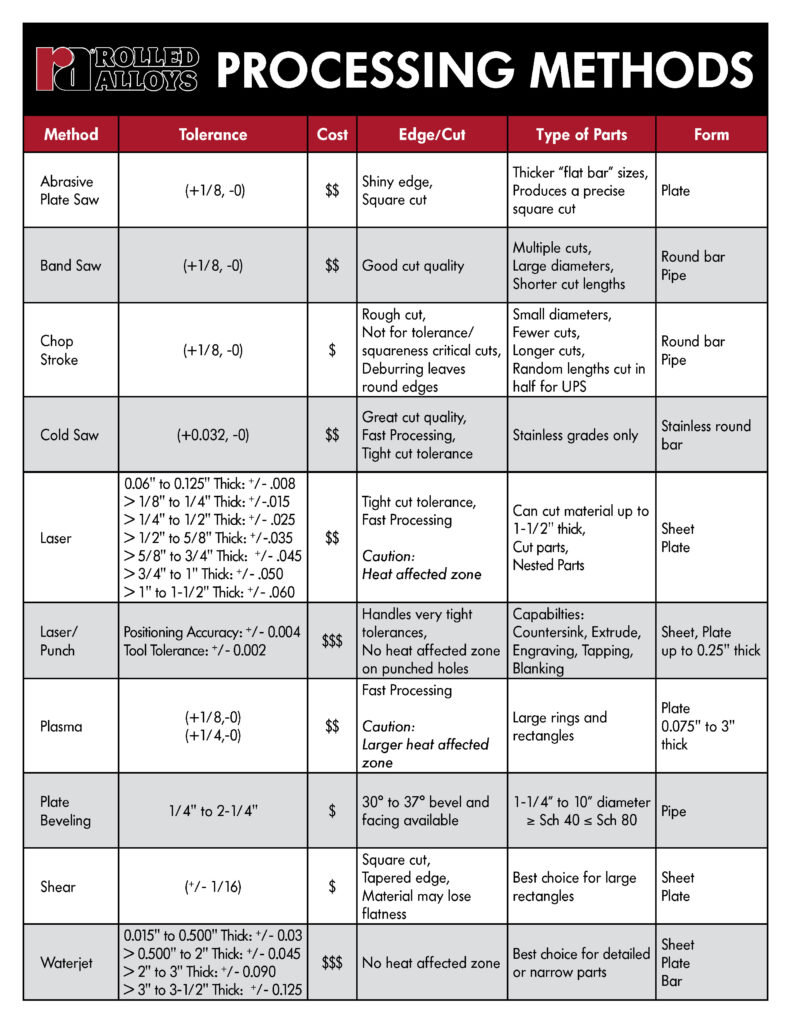

Rolled Alloys strives to be a one-stop shop for our customers by providing a variety of services and processing methods to the many industries we serve. With so many options, we understand that it can be hard to know for sure which processing method is best for you. We realize that it is easy to get in the habit of placing the same order for material you use often (hey, if it isn’t broke don’t fix it, right?).

So, we wanted to provide a resource that compares our processing methods to help you select the best cutting option for your price range. In the chart to the right, we have listed each of our processing methods along with the approximate tolerance, cost, edge/cut, type of parts (this does not mean that type of processing is limited to those parts, but these are parts that we know turn out well), and form.

This chart should make it easier when selecting a processing option for your next order, but please also keep in mind our large inventory of stock size and drop pieces.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.

How Titanium Sponge and Scrap Become Final Products

Titanium sponge and scrap are the starting materials for producing titanium ingots and slabs. Through processes like vacuum arc remelting (VAR) and hearth melting, these materials are refined into high-purity forms that are then forged, rolled, and finished into titanium plates, bars, and components.

Alloying Elements Explained

Alloying elements play a critical role in shaping the strength, corrosion resistance, and performance of metals. This article breaks down the most common alloying elements, explains how they affect material properties, and provides guidance for choosing the right alloy for any application.