Reasons Why Duplex Stainless Steels are Replacing the 300 Series

Explore the four key benefits of duplex stainless steel: high strength, superior corrosion resistance, ease of fabrication, and cost-effectiveness. Understand why 2205 is favored over 304/304L and 316/316L for industrial applications.

The History and Uses of AL-6XN®

AL-6XN® was developed to improve the corrosion resistance of AL-6X in seawater environments, offering better performance in resisting…

Chloride Stress Corrosion Cracking (CSCC) in Indoor Swimming Pools

Explore the causes and solutions for chloride stress corrosion cracking (CSCC) in 300 series stainless steels used in indoor swimming pool environments.

Best Practices When Using Specialty Materials for SWRO Feed and Brine Reject Lines

Best Practices When Using Specialty Materials For SWRO Feed and Brine Reject Lines Selecting materials for Saltwater Reverse Osmosis (SWRO) applications demands precision and expertise. In this comprehensive guide, we delve into the evolution of material selection strategies, exploring corrosion-resistant alloys and their performance in SWRO environments. WATCH THE PRESENTATION BELOW https://youtu.be/M9VreafUSBc PRESENTATION SLIDES SUMMARY […]

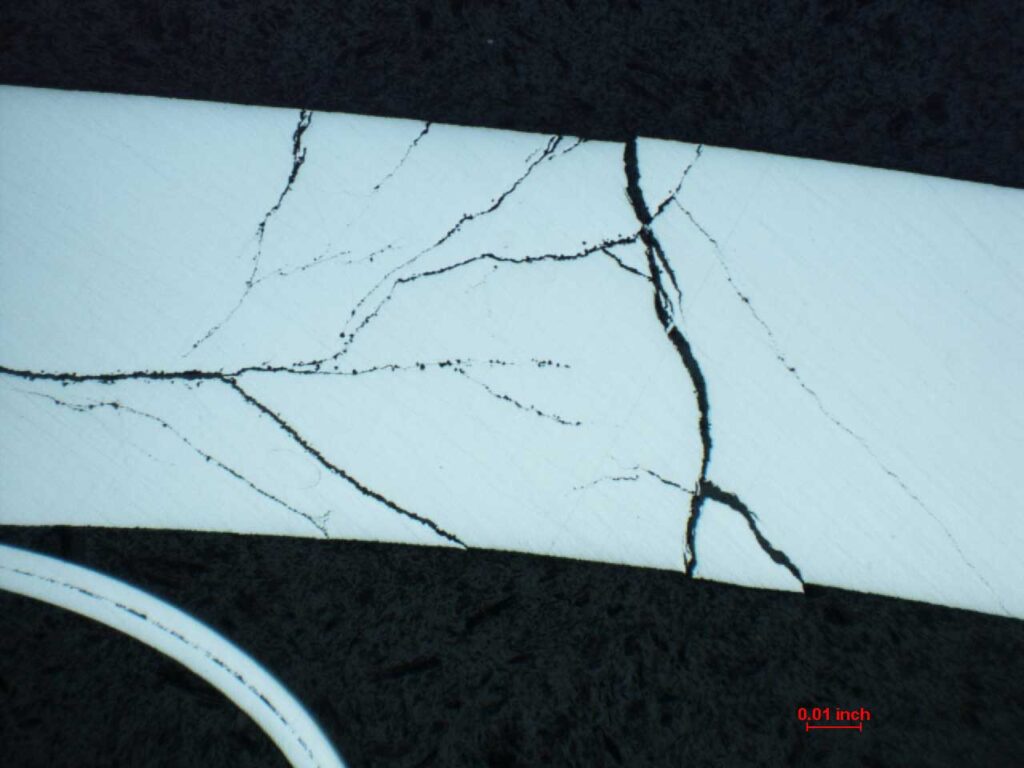

Stress Corrosion Cracking

Stress Corrosion Cracking (SCC) is a cracking phenomenon that is crucial to consider when working with specialty alloys. SCC is often associated with chlorides but can also occur with exposure to caustic and other corrosive media. The most common type of stress corrosion cracking in stainless steels occurs in chloride environments, which will be the focus of this discussion.

Hydrogen Sulfide – NACE MR0175/ISO 15156 & NACE MR0103

Hydrogen Sulfide -MR0175/ISO 15156 & MR0103 NACE International has developed two significant standards relative to the use of materials in hydrogen sulfide-bearing environments. MR0175/ISO 15156, Petroleum and Natural Gas Industries – Materials for use in H2S-containing Environments in Oil and Gas Production; and MR0103, Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments. […]

How Stainless Steel Rusts

How Stainless Steel Rusts All grades of stainless steel contain a minimum of 10.5% chromium within their chemical composition which allows for them to form a continuous protective oxide layer along their surface. This oxide layer is what makes stainless steel resistant to rusting and other forms of corrosion. Although stainless steel has this protective […]

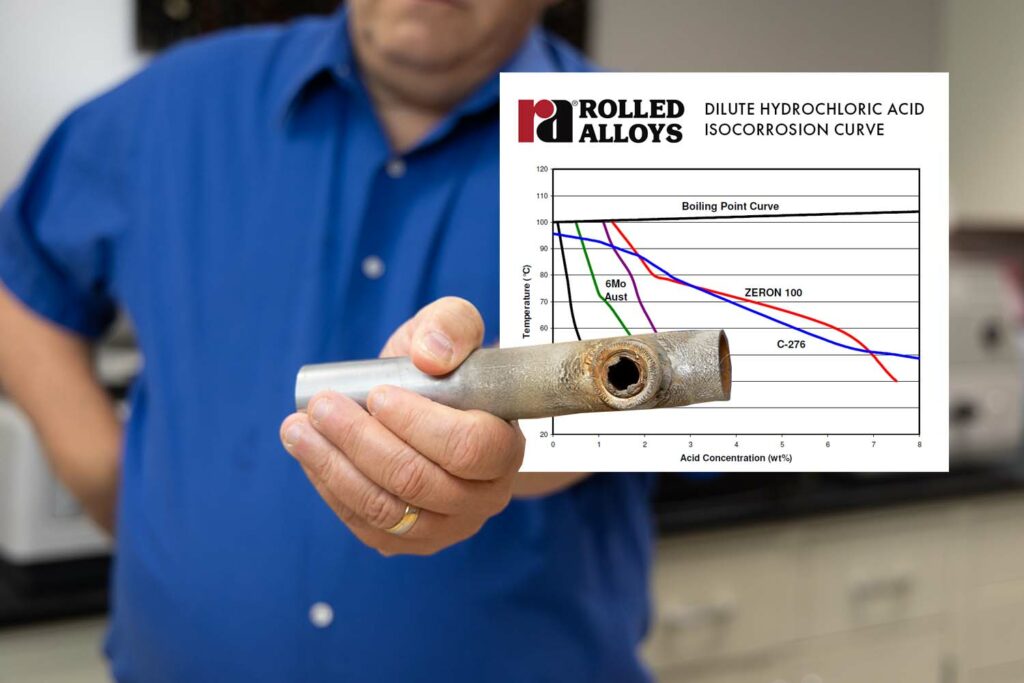

Alloys and Acid Performance

Alloys and Acid Performance Isocorrosion Curves for Dilute Hydrochloric Acid and Sulfuric Acid https://youtu.be/5X-Un5Hwnz4 Marc Glasser is the Director of Metallurgical Services at Rolled Alloys. He’s been with RA for nearly 9 years and has worked as a metallurgist in Material Science for 40 years. He has a Bachelor’s Degree in Metallurgical Engineering from Rensselaer […]

Stop Corrosion Before It Starts

Stop Corrosion Before It Starts Corrosion can occur when an alloy is exposed to moisture and other elements or chemicals which cause the material to deteriorate. Rolled Alloys has put together a list of tips to help you avoid corrosion. Choose Stainless Steel: Although all metals can corrode, stainless steels are more resistant to corrosion […]