Instant Pricing on Nickel, Stainless Steel, Duplex, and Titanium

Get instant pricing and availability for nickel, stainless steel, duplex, and titanium—all in one place.

New and Expanded Stock for 2025

New Titanium, Stainless, Nickel and Cobalt in Stock Now – CP Ti Grade 2, 635, 718 and More!

History and Uses of Alloy 800

Discover the evolution of Alloy 800, from its origins during the 1950s to modern derivatives like Alloy 800H/800HT. Learn about its high-temperature strength, petrochemical applications, and commercial availability today.

New Bar Stock Available

New Round and Flat Bar Products in Stock at Rolled Alloys

The History and Uses of AL-6XN®

AL-6XN® was developed to improve the corrosion resistance of AL-6X in seawater environments, offering better performance in resisting…

Machining Stainless Steel and Nickel Alloys

In most circumstances, machining stainless steel and nickel alloys is more difficult than machining low-alloy steels. However, there are a wide range of compositions, and some grades can have better machinability than mild steel.

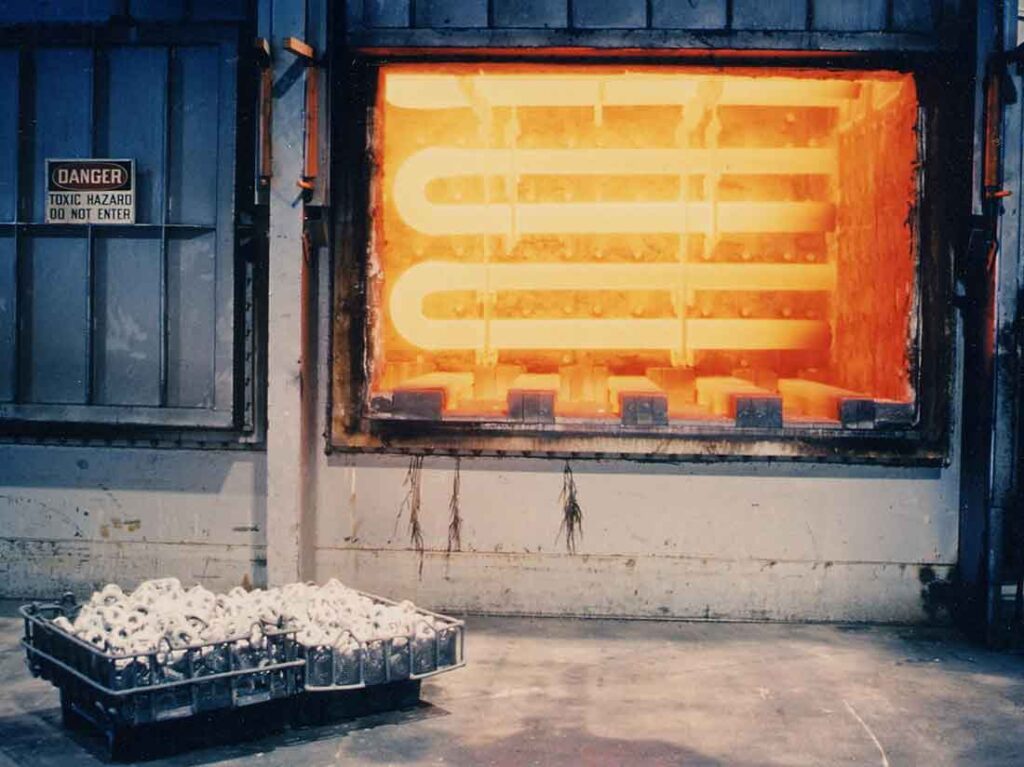

70 years in the Thermal Processing Industry

Over the past 70 years, we have been committed to servicing the thermal processing industry. In 1953, the year Rolled Alloys was founded, we introduced RA330 as a wrought replacement to cast HT. Due to RA330’s versatility and availability, it remains the most widely used wrought alloy by commercial heat treaters.

Inclusions in Specialty Alloys

When molten metal (steel, stainless steel, or nickel alloys) solidifies, the center of an ingot or slab is the last to freeze. While non-metallic impurities (oxides, nitrides, sulfides, silicides) settle throughout the ingot or slab, the greatest concentration of these inclusions settle along the solidification front…

What is Sensitization and How to Avoid It?

What is Sensitization and How to Avoid It? Sensitization is a phenomenon that can occur in stainless steel and even some nickel alloys. It is a critical concept that needs to be understood as it can adversely affect the performance of stainless steel and nickel alloys. Sensitization is the precipitation of carbides at grain boundaries […]

Hydrogen Sulfide – NACE MR0175/ISO 15156 & NACE MR0103

Hydrogen Sulfide -MR0175/ISO 15156 & MR0103 NACE International has developed two significant standards relative to the use of materials in hydrogen sulfide-bearing environments. MR0175/ISO 15156, Petroleum and Natural Gas Industries – Materials for use in H2S-containing Environments in Oil and Gas Production; and MR0103, Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments. […]