RA 253 MA Delivers High-Temp Performance in Industry Feature

Rolled Alloys has been featured in Heat Treat Today with the article, “A Microalloyed Solution for High-Temp Applications.”

Instant Pricing on Nickel, Stainless Steel, Duplex, and Titanium

Get instant pricing and availability for nickel, stainless steel, duplex, and titanium—all in one place.

New and Expanded Stock for 2025

New Titanium, Stainless, Nickel and Cobalt in Stock Now – CP Ti Grade 2, 635, 718 and More!

New Bar Stock Available

New Round and Flat Bar Products in Stock at Rolled Alloys

Reasons Why Duplex Stainless Steels are Replacing the 300 Series

Explore the four key benefits of duplex stainless steel: high strength, superior corrosion resistance, ease of fabrication, and cost-effectiveness. Understand why 2205 is favored over 304/304L and 316/316L for industrial applications.

Manganese Substitution Grades of Stainless Steel

Explore the evolution of stainless steel with manganese substitution grades, offering cost-effective solutions for industries like appliances and food equipment.

Best Practices When Using Duplex Stainless Steels

Best Practices When Using Duplex Stainless Steel Watch the Presentation Below https://www.youtube.com/watch?v=CobElRfi9vk PRESENTATION SLIDES Welcome, readers, to our exploration of best practices when utilizing duplex stainless steels. In today’s blog, we delve into the insights shared during a recent webinar conducted by Rolled Alloys, where Dr. Glenn Byrne, an esteemed expert in metallurgy, provided invaluable […]

Machining Stainless Steel and Nickel Alloys

In most circumstances, machining stainless steel and nickel alloys is more difficult than machining low-alloy steels. However, there are a wide range of compositions, and some grades can have better machinability than mild steel.

Ferrite Content in Austenitic Stainless Steels

Ferrite Content in Austenitic Stainless Steels The basic 300 series stainless steels like 304/304L and 316/316L have an austenitic microstructure and are non-magnetic. In the annealed condition, they are essentially free of ferrite, which is magnetic. Cast products of these alloys typically have some ferrite present. These alloys also form some ferrite when they are […]

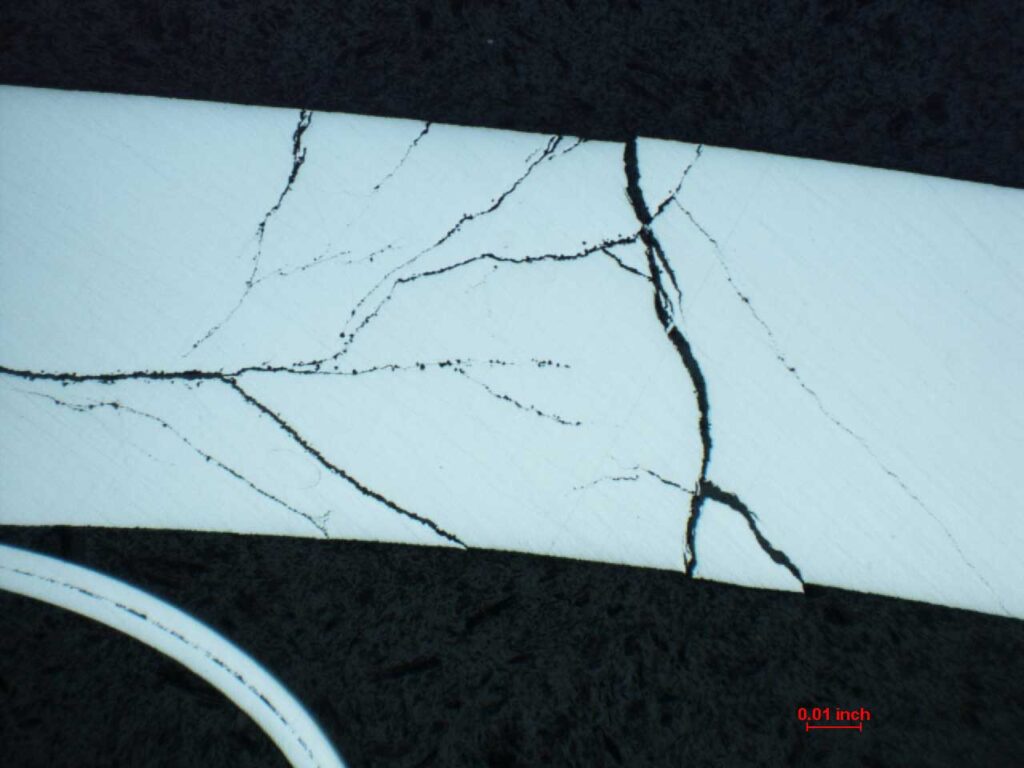

Stress Corrosion Cracking

Stress Corrosion Cracking (SCC) is a cracking phenomenon that is crucial to consider when working with specialty alloys. SCC is often associated with chlorides but can also occur with exposure to caustic and other corrosive media. The most common type of stress corrosion cracking in stainless steels occurs in chloride environments, which will be the focus of this discussion.