Home » News & Articles » The History and Uses of AL-6XN®

In response to the need for a cost-effective alloy that could resist brackish water or seawater environments, stainless alloys with even higher levels of chromium and molybdenum were developed. This need resulted in the development and introduction of AL-6X™ in the early 1970s by ATI.

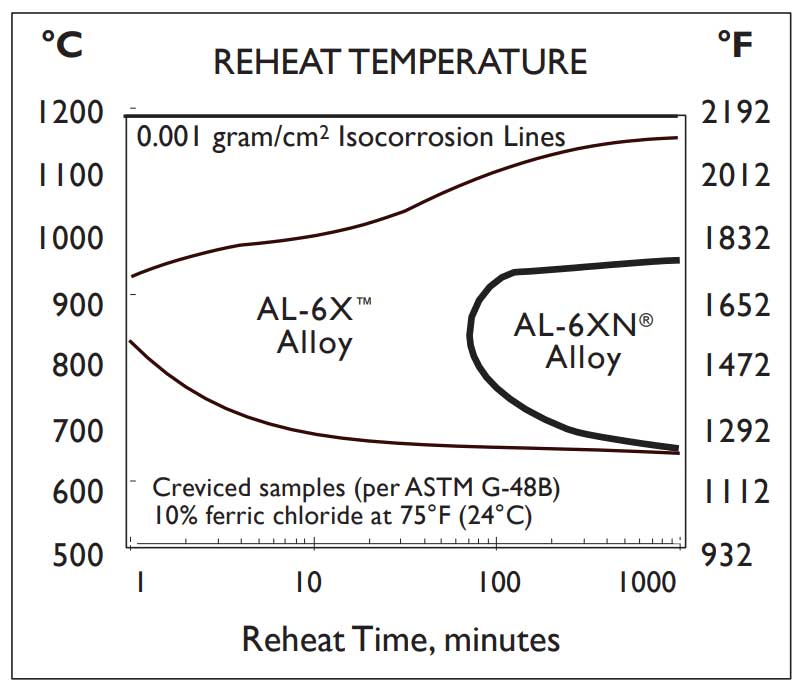

One significant problem with AL-6X was that the product forms and sizes were limited due to metallurgical reasons. The alloy’s high chromium and molybdenum content rendered AL-6X susceptible to forming sigma phases upon slow cooling between 1000°F – 2100°F. Flat products thicker than 0.1875″ could not be cooled quickly enough to prevent this formation, which would hamper the material’s corrosion resistance and toughness.

Nitrogen was found to be effective in retarding the formation of sigma phase and enhanced the effects of chromium and molybdenum by improving resistance to pitting, crevice corrosion, and stress-corrosion cracking. The figure below shows the times and temperatures that AL-6X and AL-6XN® tend to form sigma phase. Therefore, AL-6XN® was developed as an improvement over AL-6X. Both alloys have the same elemental composition except AL-6XN® contained an intentional addition of 0.18% – 0.25% N.

Sigma Phase Time Temperature Transformation Curves

In 1977, Avesta, now Outokumpu, developed their own super austenitic alloy, 254SMO®, but AL-6XN® became the more widely used and accepted alloy due to a market development relationship with Rolled Alloys. Rolled Alloys played an instrumental role in developing the sources to ensure the supply of all product forms and maintain an inventory of these products in various sizes.

AL-6XN® has various use cases across different industries. It is known for its exceptional performance in coal-fired flue gas desulfurization (FGD) systems and seawater applications in the power industry. Other sectors have also benefited from AL-6XN®’s chloride and acid resistance, leading to increased usage in the chemical process industry (CPI). Additionally, it has shown good resistance to microbiologically influenced corrosion (MIC). The food and pharmaceutical industries have used AL-6XN® for decades in situations where 316/316L was not sufficient. AL-6XN® is also utilized in offshore oil and gas environments, pulp bleaching applications, service water piping, LNG transportation and storage, as well as reverse osmosis desalination systems.

ATI is the only manufacturer with a long-standing history of superior performance, quality, and expertise in producing AL-6XN® (N08637). While other producers have attempted to supply substitute materials that meet the UNS number’s broad chemistry range, they sometimes offer different levels of performance or integrity. Rolled Alloys exclusively stocks genuine AL-6XN® products produced to the highest quality standards.

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

The Value of Cut Part Inspection

Modern metal fabrication demands fast, accurate cut metal inspection to keep up with high-volume production and tight tolerances

RA 253 MA® vs 309/310

Comparing RA 253 MA® and 309/310: Performance, Durability, and Applications

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

AL-6XN Case Study

AL-6XN® Case Study AL-6XN® Resisted corrosive environments at indianapolis power and light for over 5 years Specifications UNS: N08367 ASTM: B 688, A

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.