Home » News & Articles » Understanding High-Temperature Distortion of Metals

When metals are subjected to high temperatures, they undergo expansion. The extent of expansion is measured in terms of the coefficient of thermal expansion. This physical property is frequently cited for various engineering materials.

In the thermal processing industry, neglecting thermal expansion is a leading cause of failure of thermal processing equipment.

The growth due to thermal expansion can be surprising to those unfamiliar with designing high-temperature equipment. At 1800°F, a four-foot-long piece of 310 will expand nearly 7/8”. This growth must be accounted for. If not, one or multiple things may occur, including:

1) Buckling

2) Structural Distortion

3) Cracking of Welds

Austenitic stainless steels expand at nearly twice the rate of low alloy steels and four times the rate of ceramics. These differences in thermal expansion can create significant tensile or compressive stresses when the materials are combined for use in a cyclic thermal environment.

Another consideration is that heating and cooling are usually not uniform. Uneven temperatures, also known as thermal gradients, create stresses within the metal, often causing distortion and the poor thermal conductivity of stainless steel contributes to more significant thermal gradients. Thermal gradients of as little as 200°F from one side of a plate to the other are sufficient to create stresses that can exceed the yield strength of the material. Under cyclic conditions, distortion will become more severe with each cycle. Higher-strength alloys often permit thinner cross-sections, reducing distortion due to thermal gradients.

Distortion of components can also arise from relieving residual internal stresses. When mill products are produced, they are straightened or flattened after annealing. These residual stresses are what keep products straight and flat. There may also be residual stresses from fabrication. These stresses can be relieved once the components are exposed to elevated temperatures, resulting in potential distortion.

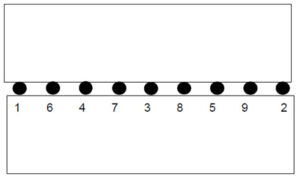

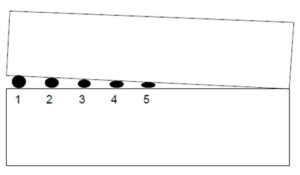

Lastly, it is crucial to distribute heat as evenly as possible to prevent distortion when welding. Welding consecutive tacks will cause the joint to close. Tack welds should be staggered over the joint to reduce distortion. A similar approach is necessary when making circumferential welds.

AL-6XN® Case Study

Coal-fired power plants generate flue gas as a byproduct of combustion. In many modern plants, especially those burning coal with high sulfur and chloride content,

RA 253 MA® vs 309/310

The main difference between RA 253 MA and both 309 and 310 stainless steel lies in alloy composition and resulting high‑temperature performance. RA 253 MA

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut

Never Miss an Update - Subscribe Today!

Get application insights, material guides, and technical answers straight from the leaders in high-performance alloys.

Share:

QUOTE, BUY, TRACK

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

Latest Articles

AL-6XN® Case Study

Coal-fired power plants generate flue gas as a byproduct of combustion. In many modern plants, especially those burning coal with high sulfur and chloride content, this flue gas can become highly corrosive to carbon steel and even conventional stainless steels.

RA 253 MA® vs 309/310

The main difference between RA 253 MA and both 309 and 310 stainless steel lies in alloy composition and resulting high‑temperature performance. RA 253 MA contains micro‑alloy additions of cerium, silicon, and nitrogen, which enhance oxidation resistance and creep strength at elevated temperatures. In addition, RA 253 MA has a lower overall nickel and chromium content, making it less susceptible to fluctuations in commodity pricing when compared to 309 and 310 stainless steels.

5-Axis Waterjet Beveling

A 5-axis waterjet cutting machine is an advanced CNC cutting tool that uses a high-pressure stream of water mixed with abrasive (usually garnet) to cut through metals and other materials.

A Smarter Way to Order Metal Online

Introducing updates to the Rolled Alloys eCommerce experience designed for speed, clarity, and control.

2026 Trade Show Schedule

Connect with our team in person throughout 2026 at these key industry events. Explore our full trade show schedule to discover where we’ll be exhibiting all year long.