Nitric acid

Nitric acid is the second largest commodity mineral acid, following behind sulfuric acid. It is a strong oxidizing acid and is used in CPI processes, the production of fertilizers and explosives, and is one of the principle ingredients for pickling stainless and chromium bearing nickel alloys.

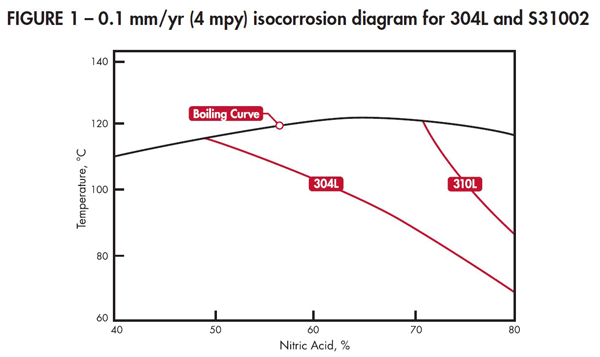

Type 304L stainless is widely used in the handling and storage of nitric acid up to 60% concentration and up to the atmospheric boiling point (Figure 1 above). It has been commonly used for cooler condensers operating as hot as 200°C (390°F). The stabilized 18-8 grades, 321, and 347 are also used. Nitric acid will intergranularly attack areas that suffer from carbide precipitation so that “L” grades or stabilized grades should be used where welding is involved.

Increasing chromium content is generally beneficial in improving resistance to nitric and other oxidizing acids. A low carbon grade of 310 has been developed and marketed (S31002 or 310 NAG) specifically for nitric acid service. This grade can be useful at concentrations above 70%. In addition to attacking chromium depleted regions due to carbide precipitation, nitric acid can also attack sigma phase or other transitional phases in molybdenum bearing alloys. As a result, molybdenum bearing grades, such as 316L, are not particularly useful in nitric acid service. Duplex alloy 2205 appears to offer no advantage over 304L in pure acid. Duplex and super duplex alloys may offer some advantage in acid containing metal ions, such as pickling solutions.

Titanium alloys Grade 2 and Grade 7 can be considered at concentrations below 10% and in the 65% -90% concentration range. Zirconium is more resistant than titanium and can be used up to 65% acid at temperatures up to 230°C (450°F). It is subject to stress corrosions cracking at concentrations over 70%. Tantalum is resistant at all concentrations up to atmospheric boiling. Fuming nitric acids, with concentrations over 90%, react differently from the lower concentrations. Aluminum alloys A91100 and A95052 (and several others) are suitable at concentrations over 80% at room temperature and up to 43°C (110°F) in concentrations over 93%. Austenitic stainless steels with 4-5% silicon (18% Cr-18% Ni) are also employed at concentrations over 90%. Tantalum has been used at temperatures up to 315°C (600°F).

The process to produce nitric acid begins by passing anhydrous ammonia over a Pt-Rh catalyst at 925°C (1700°F). Alloys used for the catalyst grid have included RA333®, RA 602 CA® and Alloy 230®.

| Alloy | Notes | Concentration, % | Temperature | Time | Corrosion Rate | Ref | ||

|---|---|---|---|---|---|---|---|---|

| C | F | mm/yr | mils/yr | |||||

| 17-4PH | condition H 1075 | 25 | boiling | 5x48hr | 0.18 | 7 | 13 | |

| 17-4PH | condition H 1075 | 50 | boiling | 5x48hr | 1.2 | 47 | 13 | |

| 17-4PH | condition H 1075 | 65 | boiling | 5x48hr | 2.72 | 107 | 13 | |

| 17-4PH | H 1075 + 1% HF | 10 | 35 | 95 | 5x48hr | 38 | 1500 | 13 |

| 2250 | — | 65 | boiling | 240hr | 0.20 | 7.9 | 8 | |

| 2205 | — | 65.3 | boiling | — | 0.13 | 5.3 | 9 | |

| 304 | — | 65 | 116 | 241 | — | 0.23 | 9 | 1 |

| 304L | plus 3% HF | 10 | 70 | 158 | 4fr | 157 | 6410 | 1 |

| 316 | plus 3% HF | 5 | 68 | 155 | — | 4.18 | 165 | 1 |

| 316 | — | 10 | 90 | 194 | — | 0.22 | 9 | 1 |

| 316 | plus 2% HCI | 60 | 50 | 122 | — | 0.28 | 11 | 1 |

| 316 | A 262 C | 65 | boiling | 24hr | 0.872 | 34 | 1 | |

| 316L | — | 65.3 | boiling | — | 0.25 | 9.8 | 9 | |

| 316L | plus 3% HF | 10 | 70 | 158 | 4hr | 64.6 | 2450 | 1 |

| 317L | — | 65.3 | boiling | — | 0.21 | 8.3 | 9 | |

| 310S | plus 3% HF | 10 | 70 | 158 | 4hr | 9.36 | 369 | 1 |

| AL-6XN | plus 3% HF | 5 | 68 | 155 | — | 1.55 | 61 | 1 |

| AL-6XN | plus 3% HF | 10 | 70 | 158 | 4hr | 2.56 | 101 | 1 |

| AL-6XN | A 262 C | 65 | boiling | 24hr | 0.738 | 29 | 1 | |

| 800 | plus 3% HF | 10 | 70 | 158 | 4hr | 18.6 | 732 | 1 |

| 20Cb-3 | plus 3% HF | 10 | 70 | 158 | 4hr | 7.65 | 301 | 1 |

| 825 | plus 3% HF | 10 | 70 | 158 | 4hr | 3.02 | 119 | 1 |

| 825 | plus 1% HF | 53 | 80 | 176 | 336hr | 5.1 | 200 | 12 |

| RA333 | mill annealed | 65 | boiling | 5x48hr | 1.07 | 42 | 3 | |

| RA333 | anneal + 1250 1hr | 65 | boiling | 5x48hr | 3.96 | 156 | 3 | |

| RA333 | anneal + 1700F 1hr | 65 | boiling | 5x48hr | 0.292 | 11.5 | 3 | |

| RA333 | anneal + 1700F 1hr +1250 1hr | 65 | boiling | 5x48hr | 0.292 | 11.5 | 3 | |

| G-30 | plus 1% HF | 20 | 80 | 176 | — | 0.85 | 34 | 6 |

| G-30 | plus 6% HF | 20 | 80 | 176 | — | 3.6 | 140 | 6 |

| G-30 | plus 1% HF | 50 | 80 | 176 | — | 4.9 | 192 | 6 |

| G-30 | plus 3% HF | 10 | 70 | 158 | 4hr | 1.04 | 41 | 1 |

| G-30 | plus 3% HF | 5 | 68 | 155 | — | 0.741 | 29 | 1 |

| G-30 | — | 10 | boiling | — | 0.02 | 0.7 | 6 | |

| G-30 | — | 60 | boiling | — | 0.13 | 5.3 | 6 | |

| C-276 | — | 10 | 90 | 194 | — | <0.01 | 0.2 | 2 |

| C-276 | plus 3% HF | 10 | 70 | 158 | 4hr | 6.71 | 264 | 1 |

| C-276 | — | 65 | 116 | 241 | — | 0.74 | 29 | 2 |

| C-276 | plus 2% HCI | 60 | 50 | 122 | — | 0.21 | 8.2 | 2 |

| C-22 | plus 3% HF | 10 | 70 | 158 | 4hr | 1.71 | 67 | 1 |

| 625 | plus 3% HF | 10 | 70 | 158 | 4hr | 3.96 | 156 | 1 |

| 625 | — | 65 | boiling | — | 0.76 | 30 | 16 | |